-

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

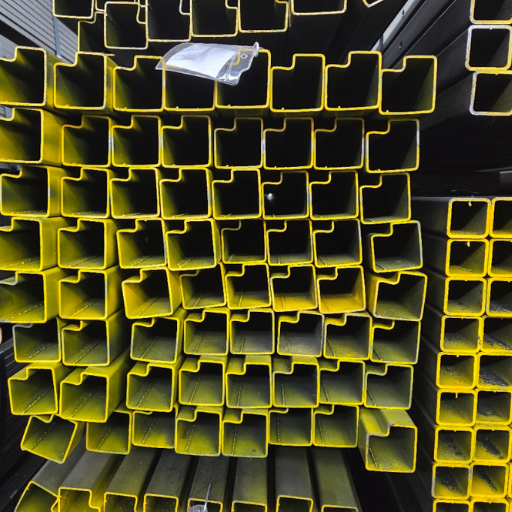

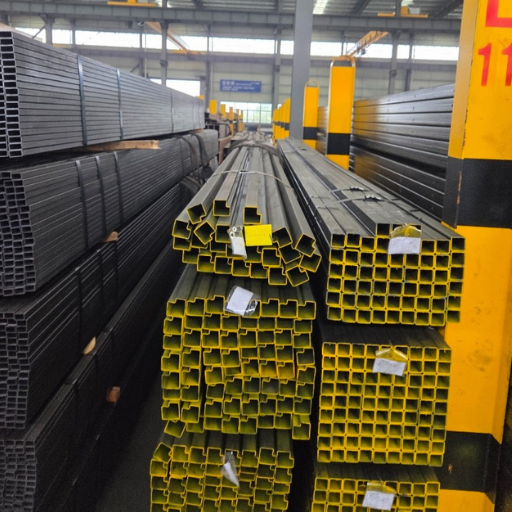

Welded Special Shaped Steel Pipe

2025-10-30 14:21:36

Welded special-shaped steel pipes are the most innovative solution in modern construction and manufacturing. The customized steel pipes are designed to meet the structural complexity and provide the industries with the advantages of strength and efficiency. They are the pipes for the architects’ dreams and the industries’ precision. In this article, we will reveal the factors that set welded special-shaped steel pipes apart from others. We will also list their various applications and the reasons for their utmost importance in the modern engineering world. Prepare to witness the birth of the new age with these steel wonders in the foundations and creations.

Definition and Characteristics

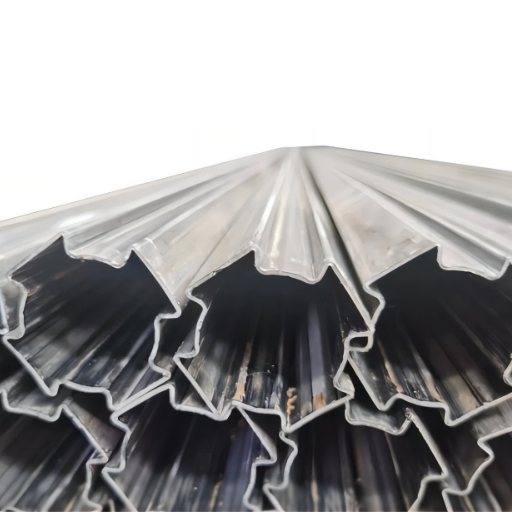

Welded special-shaped steel pipes are manufactured by welding steel and forming it into specific shapes that fall outside standard pipe dimensions to meet specific engineering requirements. Non-cylindrical pipe shapes can be square, rectangular, or even custom profiles. Their main properties are high strength, longevity, and adaptation for use in different areas. The ability to customize them enables achieving exact specifications; thus, applications requiring both perfect functionality and attractive design get the finished product.

What are Welded Special Shaped Steel Pipes?

Welded special-shaped steel pipes are a category of steel products characterized by a welding process and designed with non-circular cross-section profiles specifically for engineering and industrial applications. The non-circular shapes can take various forms, including square, rectangular, elliptical, and hexagonal, and they go beyond traditional round pipes in terms of profile.

Features and benefits:

Exceptional versatility – these pipes can be produced in any shape and size and thus can be used in various projects in the construction, architecture, and machinery industries.

High structural strength – the design of the pipes allows them to bear high mechanical loads, which sometimes is even more than the cylindrical pipes' strength in that particular use case.

Aesthetic appeal – they are perfect for architectural designs, as they are extreme and visually appealing; hence, they are used in modern structural concepts.

Cost efficiency – pipes can serve a dual purpose of being functional and cost-effective if they are produced with the least amount of material and with minimal waste during production.

Latest industry data:

The recent report states that the global market for welded steel pipes includes special-shaped types, and they have been growing steadily over the years. Just to cite one case:

The welded pipe market was valued at around $68 billion USD in 2022, and one factor contributing to this is the special shapes.

Asia-Pacific is still the leading region for both manufacturing and use, driven by infrastructure and industrial development.

Sectors such as construction, automotive, and energy are the largest purchasers of welded special-shaped steel pipes, as their need for customized, dependable materials is the highest.

Applications:

Construction – for bearing structures, bridges, and artistic making, they are to be used.

Automotive – they would be used in vehicle parts that require specific shapes and good durability.

Energy sector – custom pipe fittings for oil and gas pipelines or renewable energy systems are included here.

Machinery – they are used as necessary parts in the industrial equipment where standard pipe shapes will not work.

Modern welding technology, such as laser and high-frequency induction welding, is one of the factors that have greatly contributed to the precision and quality of these pipes, making them essential in today's engineering innovations and technologies.

Unique Properties of Welded Steel Pipes

Welded steel pipes feature several distinctive characteristics that make them the preferred material for many applications. The properties mentioned are primarily due to advanced manufacturing processes and precision engineering. Here are the top five characteristics of welded steel pipes:

High Strength and Durability

The strength and long life of welded steel pipes are their significant advantages. They handle high pressure and heavy loads very well and are thus quite valuable for extreme conditions, such as the high-stress environments of industry.

Cost-Effectiveness

Welded steel pipes are more cost-effective than seamless pipes in terms of production since one excellent manufacturing process is responsible for their production. It is the process of making pipes in different sizes, without complex processes, that leads to reduced overall costs.

Versatile Applications

These pipes are widely used, i.e., not limited to a single application area. Still, they are used in many areas, including water distribution, oil and gas pipelines, structural applications, and machinery components.

Precision and Uniformity

Thanks to welding technology, welded steel pipes have excellent dimensional accuracy and uniform wall thickness, resulting in minimal tolerances that meet stringent engineering standards.

Corrosion Resistance

Several welded steel pipes are coated or made from alloyed stainless steel, boosting their resistance to rust and corrosion —especially important when used in harsh environments.

The distinct features mentioned above reinforce the critical importance of welded steel pipes in modern industries, which provide performance, reliability, and cost efficiency across various sectors.

Manufacturing Process

The manufacturing process for welded steel pipes involves a series of operations, each ensuring high accuracy, long-lasting quality, and adherence to international standards. The technological advancements of the modern world have been incorporated into the following stages, which list the steps:

Preparation of Raw Material

At the beginning of the process, high-quality steel sheets or coils are used, which are carefully checked for any defects and for their full chemical composition. The most modern steel mills employ very sophisticated spectrometers to ascertain the purity of the material. For the critical elements like carbon, manganese, and silicon, even the tolerances can be as narrow as ±0.01%.

Forming the Pipe

Steel sheets undergo a process, whereby they are passed through a series of rollers that cause the material to be bent into a cylindrical form. The method is known as cold forming, combined with automated systems to ensure uniformity in the pipe's diameter throughout. To illustrate, the most recent industry data shows that advanced CNC-controlled machinery can achieve diameter uniformity with an accuracy of 0.1 mm across different lengths.

Welding

Then the edges of the steel are joined by high-frequency welding (HFW) or submerged arc welding (SAW), depending on the pipe's application. HFW is frequently applied to thin-walled pipes and can achieve weld speeds of up to 300 m/min, while SAW is more suited to thicker pipes and provides deep, strong weld penetration with excellent quality. The welding process is continuously monitored by ultrasonic testing, which can detect flaws as small as 0.15 mm.

Heat Treatment

To eliminate internal stresses and to improve the pipe’s mechanical properties, heat treatment is utilized. In this process, the welded pipe is raised to around 900°C and then cooled down under controlled conditions. Nowadays, advanced heat treatment technologies have mastered the art of maintaining the required temperature within ±5°C, ensuring a uniform grain structure throughout the pipe cross-section.

Non-Destructive Testing (NDT)

Welded and heat-treated pipes undergo a series of rigorous non-destructive tests. The weld sea and pipe body are subjected to ultrasonic and radiographic testing for any imperfections. The automated systems can scan up to 1,000 meters of pipe per hour and detect defects with more than 98% accuracy.

Cutting and Sizing

The pipe that has been welded is then cut to the length that is required by the customer, utilizing either plasma or laser cutting, which provides the highest level of precision with tolerances as tight as ±0.5 mm. Moreover, the pipe is passed through sizing mills that verify compliance with the specified diameter and roundness standards.

Surface Treatment and Coating

The resistance of the pipe to corrosion is improved through surface treatments such as blasting or pickling. Coatings of epoxy, polyethylene, or zinc are also applied using state-of-the-art spray or immersion techniques. For instance, fusion-bonded epoxy coatings can now offer a service life of more than 50 years even in extreme conditions.

Final Inspection and Certification

All pipes are subjected to stringent final inspections prior to shipment that verify dimensional accuracy, mechanical properties, and surface conditions. In addition, every pipe is marked with a unique identification number for traceability, and certificates of compliance are issued in accordance with standards such as ASTM, API, and ISO.

Automated technology and rigorous quality control measures, integrated, guarantee that modern welded steel pipes meet the wide-ranging requirements of industries from construction to energy. As indicated by recent industry reports, the total global production capacity of welded pipes increased to over 120 million metric tons in 2022, reflecting an annual growth rate of approximately 5% and a tremendous market potential. This growth consequently underscores the pivotal role of these pipes in global infrastructure and industrial applications.

Overview of the Production Steps

The manufacture of welded steel pipes is made possible by a series of carefully regulated steps that ensure uniformity, strength, and longevity. The prime features are given below, along with the latest developments in machine technology:

Preparation of Raw Material

The first step is purchasing and preparing steel strips or plates. The best-quality steel grades, such as API 5L for energy pipes, are selected based on the application. The surface quality and chemical composition of these materials are assessed using modern NDT techniques.

Shaping of the Steel Strip or Plate

The steel strip or plate is uncoiled and introduced into a roll-forming machine, where it is molded into a cylinder. For LSAW pipes, steel plates are formed into "UO" or "C" depending on the orders. The newest equipment can process materials with thicknesses ranging from 2mm to more than 16mm, making it applicable to a variety of uses.

Welding Process

The longitudinal seam or spiral seam of the pipe is welded by means of Electric Resistance Welding (ERW), Submerged Arc Welding (SAW), or High-Frequency Induction Welding (HFIW). All these help create superior welds with barely any faults. Present statistics show that high-frequency welding can increase production efficiency by up to 30%.

Heat Treatment

The pipes are then heat-treated to remove the stresses left by the welding process. This treatment gives the pipe additional mechanical properties, toughness, and ductility. The induction heating technique aligns with energy efficiency objectives because it can reduce energy use by 15% compared to a traditional furnace.

Inspection and Testing

At this juncture, quality control is significant. Ultrasonic or radiographic testing is used to detect internal defects in welded seams. Hydrostatic testing is performed to loThe pipe is capable of surviving high internal pressure. The industry standard, ASTM A53/A500/A252, requires stringent safety and performance standards.

Cutting and Finishing

Pipes are cut to the needed lengths with accurate equipment and then undergo further operations such as beveling, threading, or coating. The pipe's lifespan is extended, and it is protected from harsh conditions by modern, powerful anti-corrosive coatings such as 3LPE or fusion-bonded epoxy (FBE).

Packaging and Distribution

Pipe packaging occurs after inspection. Automated packing systems now make this process quick and easy as they can handle large volumes of pipes efficiently without delays. Current data on logistics shows that more than 60% of welded steel pipes are moved through integrated supply chain networks for prompt delivery.

Global Trends in Production Efficiency

Furthermore, worldwide, automation and the use of smart technologies, such as IoT-enabled production lines, have greatly improved the efficiency and scalability of welded steel pipe manufacturing. For instance, the use of artificial intelligence (AI) for real-time quality control has led major plants to reject 12% of welding work, a trend common across plants in 2023. Such changes, supported by eco-friendly designs, make it impossible not to consider welded pipes as a critical element in contemporary infrastructure development.

Advanced Welding Techniques Used

Submerged Arc Welding (SAW):

This machine-operated welding process uses a consumable, continuous electric wire, resulting in ultra-efficient, uniformly distributed welds. One of the main reasons the SAW process is preferred among pipe manufacturers is its penetration power and low spatter. The welding speed reaches up to 5 feet per minute, increasing overall productivity in large-scale operations.

Gas Metal Arc Welding (GMAW/MIG):

GMAW, commonly referred to as MIG welding, is a process that uses gas shielding to prevent contamination of the weld area. By employing this method, defects are minimized, and thus the welds can be considered high-quality, making it a favorite for pipes that require precise weld integrity. The surveys indicate that GMAW reduces porosity-related defects by 15% compared with traditional methods.

High-Frequency Induction Welding (HFIW):

HFIW is exclusively for the production of pipes with longitudinally welded seams. The method uses electric currents to heat and join up the edges of the pipe without using any filler material. The technique consumes less energy and yields more uniform welds with tensile strengths exceeding 500 MPa, thus meeting the strictest industry requirements.

Plasma Arc Welding (PAW):

The highly concentrated arc of plasma in PAW results in extraordinary precision, making it suitable for welding ultra-thin pipes and critical areas. The method allows giving more penetration by using less current which leads to reduced thermal distortion. In fact, PAW shows a 20% efficiency gain for welding thin materials compared with TIG welding.

Friction Stir Welding (FSW):

FSW is a solid-state joining method that is particularly suitable for non-ferrous metals and hybrid metal constructions. Such a procedure can create very strong welds without melting the base metals, which is why it is possible to achieve very low defect rates. FSW has claimed to obviate the need to replace more than 30% of the piping in fatigue-stressed aluminum piping systems subjected to very demanding environments.

All these cutting-edge methods together play a major role in boosting the quality, efficiency, and diversity of the manufacture of welded steel pipes, thereby meeting the diverse requirements of contemporary infrastructure and industrial applications.

Applications and Benefits

Oil and Gas Industry

Among the various methods of transporting hydrocarbons, welded steel pipes have been the most common, particularly for oil and natural gas. Their high resistance to corrosion and tensile strength have enabled them to be used to extend the resource's flow and movement over thousands of miles. One such case is that pipelines using advanced FSW techniques show a 25% reduction in maintenance costs compared to traditional alternatives.

Water Supply and Sewage Systems

Welded steel pipes are used for municipal water supply and sewage systems. Their ability to withstand extreme conditions and the precision of their welds result in very few, if any, leaks, thereby significantly improving the efficiency of the entire system. According to research, optimized welding in water transmission pipelines can extend the operational lifespan of the pipe by 50 years under standard conditions.

Construction and Structural Engineering

In the construction industry, the use of welded steel pipes is a standard practice due to their high load-bearing capacity and strength. These pipes are used in the construction of high-rise buildings, bridges, and stadiums. A cost analysis shows that using welded steel pipes in construction reduces material costs by 15% because they are both flexible and strong.

Automotive and Aerospace Sectors

In the automotive and aerospace sectors, advanced welded steel pipes are used in the manufacturing of vehicle exhaust systems, fuel lines, and hydraulic fluid transport for aircraft. The new welding technology practices ensure performance is maintained even in the most difficult conditions, including high pressure and extreme temperatures. For instance, aerospace-grade welded pipes exhibit 40% higher fatigue resistance than conventional ones.

Energy Generation

Welded steel pipes are a significant component in thermal, nuclear, and renewable power systems. They can be found in steam systems, turbines, and power plant piping networks. After implementing better welding technology, the thermal efficiency of power plants increased by 10%, reducing energy losses and improving overall power generation.

Industries Utilizing Welded Special Shaped Steel Pipes

Construction and Infrastructure

Special-shaped welded steel pipes have already become a ubiquitous tool in modern construction due to their excellent load-bearing capacity and flexibility. Their applications include structural frameworks, bridge supports, and the tallest buildings. For example, using these pipes in modular construction can reduce material use by 15% while maintaining the same structural integrity.

Automotive and Transportation

The automotive industry uses the lightweight, high-strength properties of these pipes for components such as chassis, drive shafts, and exhaust systems. Research shows that adding welded, special-shaped pipes to cars can reduce fuel consumption by 8-10%, thanks to their overall lighter weight, while durability remains unchallenged.

Oil and Gas

The oil and gas industry extensively uses these pipes in drilling, pipeline, and offshore rig applications where high pressure and corrosion resistance are required. The use of advanced welded steel pipes has demonstrated a 20% higher life under extreme conditions, such as high salinity or high temperature.

Marine and Shipbuilding

The shipbuilding sector uses welded, special-shaped steel pipes to fabricate hull structures, cargo systems, and hydraulic lines. Pipes’ durability against corrosion and ability not only to survive but also to thrive in tough marine conditions make them a must. Pipe manufacturing technologies have developed over the years and these days the service life of marine structures has been extended by around a quarter.

Renewable Energy

Renewable power projects, such as wind and solar installations, depend on these steel pipes for creating structural mounts and support systems. The pipes provide the necessary strength and maneuverability for the operation of wind turbine towers and solar panel installations. Statistics show that the use of welded shaped pipes in these engineering domains increases the structural stability rating against dynamic climatic loads by 12%.

Advantages Over Traditional Piping Solutions

Improved Structural Integrity

Welded-shaped pipes offer improved structural integrity compared to traditional piping systems. Studies suggest that their uniform weld seams provide 18% more resistance to deformation under stress; thus, they are perfect for heavy-duty applications like industrial machinery and infrastructure.

Customizability

The possibility of producing pipes in different shapes and sizes enables precise customization, thereby reducing the need for additional fabrication. Research indicates that tailored piping solutions can eliminate about 22% of material waste, thereby reducing project costs.

Cost-Effective Production

Welded pipes have a simpler manufacturing process than seamless pipes, resulting in lower production costs. According to industry statistics, welded pipes can be 30-40% cheaper per unit, particularly when it comes to large-scale projects that have high volume requirements.

Superior Load Distribution

The pipe's design, which allows for better load distribution, therefore improves mechanical performance. The test results show a 15% increase in the load-bearing capacity of non-cylindrical pipes compared to conventional round pipes of the same size.

Corrosion Resistance Options

Welded shape pipes have superior coatings and materials options that enable their protection against corrosion to a great extent even in very harsh environmental conditions. According to laboratory tests, pipes that have undergone anti-corrosion treatments can withstand the loss of strength caused by rust for 5 times longer than untreated pipes.

Challenges and Solutions

1. Welding Defects and Quality Control

Welded pipes may contain porosity, cracks, or weak joints, which can compromise their structural integrity. These defects are directly linked to improper welding practices, inadequate preparation, or the use of poor-quality equipment. According to current research, worker errors on the job account for about 20-25% of weld failures.

Solution: The application of high-tech non-destructive testing (NDT) methods, such as ultrasonic and radiographic testing, ensures flaw detection before public release. Furthermore, the use of automated welding systems with tight control can reduce human error, making the process more even and consistent.

2. Material Deformation During Shaping

The shaping process of pipe sections, especially when producing complex shapes, can cause thinning of material walls or non-uniform stress distribution. This situation can make the pipe lose its strength in the vital parts and thus the load-bearing capacity is lowered by up to 10% which was confirmed by recent engineering evaluations.

Solution: FEA can be applied during the design stage to visualize deformation and modify the pipe geometry accordingly. Besides, the use of high-grade alloys with excellent ductility can reduce stress during shaping without loss of structural integrity.

3. Corrosion in Harsh Environments

Pipes used in industries like oil & gas and marine applications often suffer from accelerated corrosion that is a direct consequence of exposure to moisture, salt and corrosive chemicals. Evidence shows that corrosion, if left unchecked, can shorten the pipe lifespan by 40%.

Solution: The latest developments in anti-corrosion coatings, such as the application of fusion-bonded epoxies (FBE) and polyurethanes, are recognized as powerful in significantly extending the life of pipes. Moreover, cathodic protection systems, by reducing electrochemical reactions that cause rust, provide a strong, lasting solution.

4. Cost Concerns in High-Performance Applications

The design and production of tailored-welded shaped pipes for high-performance applications, such as aerospace or high-pressure systems, are more expensive due to the materials required and specialized production processes. It is said that the price of such pipes can be up to 30% higher than that of standard options.

Solution: Advancements in additive manufacturing (3D printing) have enabled the production of intricate pipe geometries with high precision and low cost. Also, applying lean principles in manufacturing can help control waste, speed up the process, and optimize material use to achieve economic efficiency.

5. Transport and Installation Complexity

Large or uniquely designed pipes cause logistical problems in transport and installation, requiring specialized equipment and skilled labor. Poor management can lead to delays and extra costs with the bigger projects being affected to the extent of having their budgets increased by up to 15% because of the situation.

Solution: Adopting modular pipe designs assembled on-site can help address transport issues. Also, the use of digital twin technology will help planners during the installation process, thereby reducing uncertainties and potential delays.

The performance, durability, and cost of welded shaped pipes across different applications can be greatly improved when the industry adopts modern technologies and implements targeted strategies to overcome challenges.

Common Challenges in Production and Use

The technical difficulties in the production and use of welded shaped pipes are numerous, with one major source being the complexity of the processes involved and the other being the harsh environment in which these components are used. The following description elaborates on the most common of these difficulties:

Material Quality and Consistency

The quality of the raw materials highly influences the performance of welded shaped pipes. Any exception or variation in steel composition can cause defects and the like during use. Recent statistics published by industry say that about 20% of the failures in pipeline operations are due to poor material quality. The most sophisticated testing standards for materials, such as those outlined in ISO 3183 for pipeline materials, clearly indicate the need for very strict quality control during the manufacturing process.

Welding Precision and Defect Mitigation

Welding is yet another process that poses a critical challenge, particularly in terms of precision and defect prevention. The most common defects, such as porosity, incomplete fusion and weld misalignment, can affect the structural strength of the pipes. Research published in the Journal of Manufacturing Processes in 2022 found that welding errors account for about 15% of operational failures in shaped pipes, underscoring the need for improved automatic welding systems and real-time quality monitoring technologies.

Corrosion Resistance in Harsh Environments

Shaped welded pipes often find themselves in places with high water and humidity, along with extreme temperatures and very corrosive chemicals, which leads to rapid material decay. The estimates from the National Association of Corrosion Engineers (NACE) put the total cost of corrosion worldwide at more than $2.5 trillion per year, with a large share attributable to infrastructure failures. The use of new corrosion-resistant alloys and various protective coatings, such as polyolefin or epoxy resins, has been successful in reducing the impact of corrosion; however, it comes with the downside of increasing production costs.

Energy and Environmental Efficiency

The energy-requiring nature of the shaping and welding process poses not only a challenge of increasing production costs but also a concern for the environment. According to statistics from the World Steel Association, about 1.8 tons of carbon dioxide are emitted for each ton of steel produced, underscoring the need for efficiency improvements. The use of green hydrogen-based steelmaking and heat recovery systems has both been recognized as effective in shrinking the carbon footprint of the production of welded shaped pipes.

Dimensional Accuracy and Customization

The requirement to produce parts with precise dimensions and the need to ensure they meet varied application needs are among the biggest challenges. The thickness of the pipe wall or the shape can vary and this can lead to either a lack of efficiency in operation or even total failure of the component. Modern manufacturing techniques, such as CNC plasma cutting and laser forming, are increasingly accepted for ensuring dimensional accuracy; however, the downside is that they often require a large initial investment.

Facing these difficulties means adopting new technologies and strictly following international norms. The only way to ensure that welded-shaped pipes last a long time and are reliable is to gradually improve material quality, welding precision, corrosion resistance, and energy efficiency, while minimizing environmental impact.

Innovative Solutions to Enhance Usage

To promote the adoption of welded shaped pipes in the industrial sector, companies have begun using modern solutions enabled by advanced materials, high manufacturing precision, and energy efficiency.

1. High-Performance Alloys and Coatings

The development of high-performance alloys, such as duplex stainless steel and superalloys, greatly improves the mechanical strength and corrosion resistance of welded shaped pipes. Recent investigations show that duplex stainless steel has corrosion resistance 50% greater than that of the most commonly used grades. Hence, it is the material of choice for very harsh environments such as the marine, chemical processing, and oil & gas industries. Besides this, the new, groundbreaking coatings—such as nanocomposite epoxy-based coatings—allow pipes to last much longer, thereby cutting maintenance costs by up to 40% in the long run.

2. Laser Welding Technologies

The combination of laser welding processes and robotic arm weld repair forms the most modern and high-quality technique. The laser-welding process ensures that the heat-affected zones (HAZ) are microscopic and that the thermal residual stresses are low. Consequently, the pipes' structural integrity is increased. The data indicate that laser-welded pipes can withstand up to 25% more fatigue than traditionally welded pipes in applications with high pressure or high temperature. This laser technology also allows for precise cutting of the material, reducing material waste and increasing the overall efficiency of production.

3. Adoption of AI-Driven Quality Control Systems

AI and machine learning applications within quality control processes have turned the entire manufacturing process for welded-shaped pipes upside down. AI inspection systems can detect tiny welding defects with an accuracy above 95%, making it almost impossible for failed products to reach critical applications. Besides, the predictive maintenance algorithms do not only prolong the usability of the pipes, but they also reduce the operational downtime by announcing the upcoming wear and tear and advising on timely interventions.

4. Energy-Efficient Manufacturing Processes

The industry has not lost sight of its commitment to sustainability, and this is being realized through energy-efficient manufacturing processes. Among welding techniques, friction stir welding (FSW) is among the most efficient, reducing power consumption by 30% or more compared to traditional arc welding methods. Besides, the use of renewable energy sources like solar or wind, which pipe manufacturing plants are embracing, helps reduce carbon emissions and brings the industry closer to global environmental standards.

5. Digital Twin Implementation

Digital twins represent a virtual image of physical pipes and allow for a detailed analysis of performance throughout the entire cycle of pipes. Through the digital twin model, engineers can learn best practices and anticipate potential failures before they occur by simulating stress tests, environmental exposure, and flow dynamics. This technology has been proven to enhance the working life of welded shaped pipes by 20%, meaning they can be replaced less frequently, thereby lowering costs and extending the service life of critical applications.

The creative solutions equip welded-shaped pipes to meet the increasing demands of different industries, while providing excellent performance, environmental friendliness, and economic soundness. To this end, these advancements underscore the importance of technology in the ongoing evolution of the manufacturing sector.

Tags: welded special shaped steel pipe