-

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

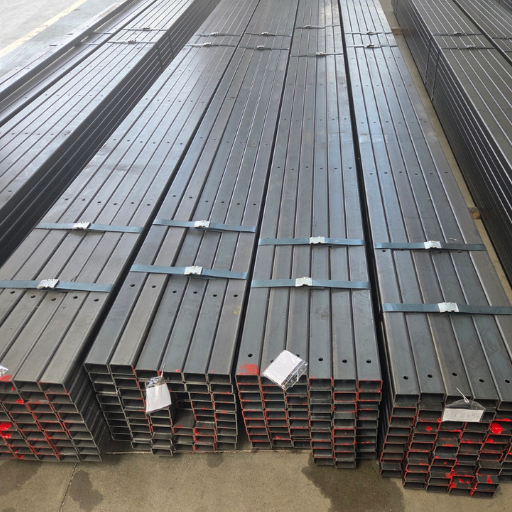

Welded Square Steel Pipe: Specifications, Properties, And Applications

2025-10-30 14:25:12

Welded square steel pipes are a must-have for numerous industries due to their versatility, strength, and low cost. These pipes are used in almost every modern development, from construction and transportation to manufacturing and infrastructure projects. The article attempts to uncover the reason behind their massive demand and use. To provide a concise yet complete picture of the specification, properties, and various uses of welded square steel pipes, this article will cover everything from extraction to recycling. It will also give readers a peek into the future of the pipe market, which will be dominated by eco-friendliness and sustainability. Thus, the article is a valuable source of information for everyone, including industry professionals, engineers, and people curious about the materials that shape our world.

Understanding welded square steel pipe

Welded square steel pipes are formed by welding steel sheets or strips at their ends to create a hollow square structure. They are not only strong but also durable and adaptable to many kinds of applications. For instance, these pipes are widely used in construction, infrastructure, and manufacturing as they can bear the weight of buildings, machines, and structures. Their consistent shape and size make them easy to install and combine with other projects, making them ideal for many industries.

What is a welded square steel pipe?

A welded square steel pipe is a hollow square tube made by welding steel around its edges. It is commonly used in construction, industrial applications, and machinery due to its strength, versatility, and ease of fabrication.

Manufacturing processes for welded square steel tubing

Welded square steel tubing production involves numerous critical processes that are crucial to its quality, strength, and durability. Here is a more comprehensive description of the five major manufacturing processes:

Material Preparation

The very first step in this process is selecting high-grade steel coils or sheets as the raw materials. After that, these materials undergo cleaning, trimming, and leveling to remove impurities or surface defects and achieve uniform thickness.

Roll Forming

The cleaned and treated steel sheets are then passed through a series of rolls that gradually form them into a square or rectangular shape using a cross-section. It is essential to maintain very tight control during this operation to ensure the dimensions remain constant and avoid distortion.

Welding

The edges of the steel that has been roll-formed are joined by welding using either high-frequency welding (HFW) or electric resistance welding (ERW). The result is a strong, uninterrupted bond along the length of the pipe. In the case of applications requiring very high strength, the welding techniques are so that the integrity of the structure is preserved.

Sizing and Straightening

The tube passes through a sizing mill right after welding, where it is carefully adjusted to achieve the correct dimensions and straightness. This will keep the finished product within the precise specifications of its intended use.

Inspection and Testing

At the very end, the tubing undergoes intensive quality control procedures, including ultrasonic testing, visual inspection, and size verification. All these measures, combined, make it possible for the tubing to be free of defects, have the correct shape, and meet industry standards.

To sum up, all these stages are indispensable for the production of high-quality welded square steel tubing which is then granted for various applications.

Specifications of Welded Square Steel Pipe

Welded square steel pipes are produced to meet a range of industry needs and applications. The following are the specifications and the main data:

1. Material Grades

The base material for welded square steel pipes is mainly high-grade carbon steel or stainless steel. The most used grades are Q195, Q215, Q235, and Q345 for carbon steel and 201, 304, and 316 for stainless steel. This selection provides pipes with strength, resistance to rust, and all-around good performance.

2. Standard Specifications

International standards guarantee consistency and quality of welded square steel pipes, for example, ASTM A500 for North America, EN 10219 for Europe, and JIS G3466 for Japan. These standards specify how square tubing should be with respect to its structural and dimensional properties.

3. Dimensions

Outer Dimensions (OD): measurements range from 10mm x 10mm to 500mm x 500mm.

Wall Thickness: usually 0.5mm to 20mm, subject to request.

Length: normal lengths are 6 meters and 12 meters; however, custom lengths are also available.

4. Mechanical Properties

Yield Strength: varies between 195 MPa and 345 MPa depending on the grade.

Tensile Strength: it ranges from 310 MPa to 630 MPa.

Elongation: it is usually at least 20%, depending on the grade and thickness.

5. Surface Finish

Surface treatments might include:

Black (oiled or untreated)

Galvanized (hot-dip galvanizing to give corrosion resistance)

Powder-coated (to beautify and protect)

6. Applications

Welded square steel pipes find their place in:

Building (for structural support, and making columns and beams)

Automotive and mechanical parts

Making fences and gates

Manufacturing of chairs and tables

By following these strict specifications, welded square steel pipes can meet various industrial requirements, providing reliability, durability, and cost-effectiveness across a wide range of applications. Always check with suppliers or industry references to confirm suitability for specific project requirements.

ASTM Standards for Steel Square Tubes

Steel square tubes are manufactured and evaluated in accordance with specific ASTM (American Society for Testing and Materials) standards to ensure their quality, safety, and reliability. The following are the major standards related to steel square tubes, with some details and specifications:

1. ASTM A500

This standard covers cold-formed, welded, and seamless carbon-steel structural tubing in round, square, and rectangular shapes. It is frequently applied for construction purposes.

Grades: A, B, C, and D

Yield Strength: 36,000 - 50,000 psi (depending on the grade)

Tensile Strength: 58,000 - 62,000 psi (depending on the grade)

Applications: Structural supports, columns, and frameworks.

Note: ASTM A500 is one of the most widely used standards for structural steel tubing due to its high strength-to-weight ratio and versatility.

2. ASTM A513

This standard specifies electric-resistance-welded (ERW) carbon and alloy steel tubing for mechanical and general engineering purposes. It also guarantees precision manufacturing and dimensional accuracy.

Types: Five types, among them Type 1 and Type 2 (the most common).

Tolerances: High-dimensional tolerances for mechanical and automotive applications.

Applications: Car parts, furniture, and compact mechanical components.

3. ASTM A847

Explicitly intended for cold-formed, welded, and seamless high-strength low-alloy structural tubing that has better atmospheric corrosion resistance. This would be the perfect application for outdoor and weather-exposed areas.

Corrosion Resistance: The use of metals like copper, nickel, and chromium in the alloy improves weathering characteristics.

Yield Strength: A minimum of 50,000 psi is required.

Applications: Road and bridge construction, highway guardrails, and outdoor installations where resistance to changing conditions is the primary selection criterion.

ASTM-Related Tolerance Ranges for Steel Square Tubes

Accurate measurement is essential for steel tubing, and ASTM standards set tolerances for dimensions and straightness:

Wall Thickness Tolerance: Generally ±10% according to ASTM standards (note that individual standards may state exact tolerances).

Size Accuracy: Permitted variations in the exterior dimensions are usually ±0.5% or ±0.020 inches.

Straightness: The maximum permissible deviation from straightness is 1/8 inch per every 10 feet of length.

Testing and Performance

Steel square tubes produced under ASTM standards undergo various tests to ensure quality:

Tensile Testing: Determination of yield strength, tensile strength, and elongation.

Bend Testing: Checks ductility and forming ability.

Visual & Dimensional Inspections: Ensures compliance with specified tolerances.

By virtue of ASTM standards A500, A513, and A847, manufacturers can offer consistent-quality steel square tubing. These specifications make the material tough, suitable for its intended use, and capable of meeting the unique requirements of industrial and engineering projects. Always verify the latest ASTM specifications and ask suppliers for project-specific information.

Dimensions and Sizes of Square Steel Tubing

Rectangular steel tubes are available in many sizes and specifications, making them suitable for a wide range of applications. Commonly provided sizes and their characteristics are listed below:

1" x 1" x 0.065" Wall Thickness

Outer Dimensions: 1 inch x 1 inch

Wall Thickness: 0.065 inch

Approximate Weight: 1.16 lbs/ft

Common Applications: Framing, furniture making, and light structural uses.

2" x 2" x 0.125" Wall Thickness

Outer Dimensions: 2 inches by 2 inches

Wall Thickness: 0.125 inches

Approximate Weight: 3.40 lbs/ft

Common Applications: Heavy-duty structural projects, machinery.

3" x 3" x 0.250" Wall Thickness

Outer Dimensions: 3 inches by 3 inches

Wall Thickness: 0.250 inches

Approximate Weight: 10.21 lbs/ft

Common Applications: Construction, industrial frameworks, and load-bearing uses.

4" x 4" x 0.375" Wall Thickness

Outer Dimensions: 4 inches by 4 inches

Wall Thickness: 0.375 inches

Approximate Weight: 20.28 lbs/ft

Common Applications: Heavy structural support, bridges, and large machinery.

5" x 5" x 0.500" Wall Thickness

Outer Dimensions: 5 inches by 5 inches

Wall Thickness: 0.500 inch

Approximate Weight: 39.25 lbs/ft

Common Applications: Superior construction and industrial applications requiring utmost durability.

The availability of these standard sizes makes it easy to meet a wide range of engineering, manufacturing, and construction requirements. It is advisable to check with the suppliers the dimensions and weight to ensure that they meet the project-specific requirements.

Mechanical Properties of Welded Square Steel Pipe

Tensile Strength

Range: 400-550 MPa

Description: Shows the maximum stress the pipe can endure if it is being stretched or pulled without breaking.

Yield Strength

Range: 250-350 MPa

Description: Marks the stress area where the pipe starts to change its shape permanently and will not go back to the original shape.

Elongation

Typical Value: 20-25%

Description: Indicates the material's ductility, meaning how much the pipe can stretch before it goes in the other direction.

Hardness

Typical Value: 120-160 HB

Description: This is the measure of the material's resistance to penetration or surface deformation by the application of a force.

Impact Resistance

Test Temperature Range: -20°C to 20°C

Description: This is the definition of the pipe's ability to withstand shocks or sudden impacts, which is a requirement for the pipe's application in dynamic or cold environments.

The properties mentioned above make welded square steel pipes good candidates for demanding applications across different industries. Always check the material specifications for the accurate values based on grade and production standards.

Characteristic Properties of Stainless Steel Square Tubes

Corrosion Resistance

Description: The metals have top-notch resistance to rust and corrosion, making them ideal for worst-case conditions in marine and industrial environments.

Application Example: Building in coastal areas has been the first choice for these materials due to their high resistance to saltwater exposure.

High Strength-to-Weight Ratio

Description: The material boasts of its lightness and strength at the same time to the point that it even adds to the integrity of the structure while reducing the weight of the entire building.

Application Example: Get the steel used in architectural frameworks and lightweight vehicle structures everywhere.

Thermal Resistance

Description: High-temperature morality is the character that usually describes the stability of thermally stressed materials.

Test Temperature Range: It varies with the steel grade, but the maximum can be up to 800°C.

Application Example: The heat exchangers and cooking equipment are the devices that are used.

Ease of Fabrication

Description: From stainless steel square tubes, one can easily obtain universal designs and projects, as cutting, welding, and forming are easy operations.

Benefit: Time-saving in production and the meeting of custom engineering needs are the two main factors supported.

Aesthetic Appeal

Description: The new, elegant designs owe their visual charm to the polished, smooth finish of stainless steel.

Application Example: Due to its sleek appearance and long-lasting sheen, the material has found major applications in furniture, railings, and decorative structures.

Comparing the strength of steel square vs. aluminum tubing

Feature | Steel Square Tubing | Aluminum Tubing |

|---|---|---|

Weight | Heavy | Lightweight |

Tensile Strength | 400-500 MPa | ~90 MPa |

Yield Strength | ~250 MPa | ~40 MPa |

Corrosion Resistance | Requires coating or treatment | Naturally corrosion-resistant |

Fabrication Ease | Harder to cut and shape | Easier to cut and shape |

Cost | Generally more affordable | Generally more expensive |

Thermal Conductivity | Lower | Higher |

Applications | Construction, heavy machinery | Aerospace, automotive, marine |

Durability | High, withstands heavy loads | Moderate, less suitable for stress |

Recyclability | Highly recyclable | Highly recyclable |

Applications of Welded Square Steel Pipe

Welded square steel pipes are in demand and widely used across various sectors due to their robust, durable, and adaptable properties. Here are five typical usages along with clear explanations below:

Construction and Infrastructure

Welded square steel pipes are among the most important materials in infrastructure development and construction. Their ability to bear heavy loads, coupled with their resistance to bending, makes them perfect for demanding applications such as scaffolding and large infrastructure.

Automotive Industry

These pipes are extensively used in the making of automotive parts, including construction, safety cages, and exhaust systems. Their strong yet light nature helps improve performance while maintaining safety standards.

Agricultural Equipment

Welded square steel pipes are used in the construction of tools, watering systems, and crop storage facilities. Their strength ensures reliability even in extreme environmental conditions for a long time.

Furniture Manufacturing

Square steel pipes are frequently used by designers to create modern pieces of furniture, such as industrial-style dining tables, chairs, and shelving units. The combination of the material's elegant and sturdy traits provides value both aesthetically and functionally.

Energy and Utility Industries

These pipes have become part of the infrastructure for gas, oil, and water distribution systems, which need very reliable pipelines. Their ability to withstand corrosion, coupled with their capacity to withstand high pressure, makes them suitable for long-term utility projects.

Structural Applications in Construction

Steel square tubes and pipes are among the most widely used materials in construction because of the durability, versatility, and strength they offer. The following are five crucial structural applications which these pipes play an essential role in:

Framework and Support Structures

Square steel pipes are used to make the skeleton of buildings, comprising beams, columns, and bracing, thus providing stability and the ability to support loads.

The strength-to-weight ratio makes them very suitable for constructing tall buildings.

Roof Trusses and Canopies

These pipes can be used to make roof trusses or canopies, as they provide strong, waterproof support for roofing materials.

Bridges and Overpasses

Square steel pipes are used in the construction of above-ground bridges and roads, providing the strength needed to withstand heavy loads and natural phenomena such as wind and rain.

Fencing and Railings

Square steel pipes are often used for fencing, railings, and barriers in both residential and commercial projects due to their corrosion resistance and modern look.

Scaffolding Systems

They can provide the necessary stability for temporary scaffolding structures in construction or renovation projects, thereby ensuring workers' safety and reliability.

Industrial Uses of Square Steel Tubing

Structural Framework

Square steel tubing is one of the main parts of a factory and warehouse structural framework because of high load-bearing capacity and long life.

Data: It depends on the steel grade used, but it can bear tensile strengths varying from 50,000 to 70,000 psi.

Support Columns and Beams

Square steel tubing is used in the construction of industrial support structures and columns, providing strong structural support.

Data: As it is a uniformly shaped material, the weight is evenly distributed, which in turn increases the stability in heavy-duty applications.

Industrial Machinery

Square steel tubing serves as the machine frame, providing a solid base for industrial equipment and tools that require strong, precise support.

Data: The resistance of the material to rusting prolongs the life of machinery even in very humid or chemically harsh environments.

Conveyor Systems

Tubing is essential for the construction of conveyor systems in manufacturing plants, which transport materials efficiently and safely.

Data: The tubing's exact measurements facilitate the smooth operation of moving parts and require little maintenance.

Oil and Gas Infrastructure

Square steel tubing is used in the oil and gas sector for pipeline support, storage racks, and other structural applications.

Data: It can withstand extreme temperatures and pressures, which meet the demands of such an environment, making the material an ideal choice.

Tags: welded square steel pipe