-

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

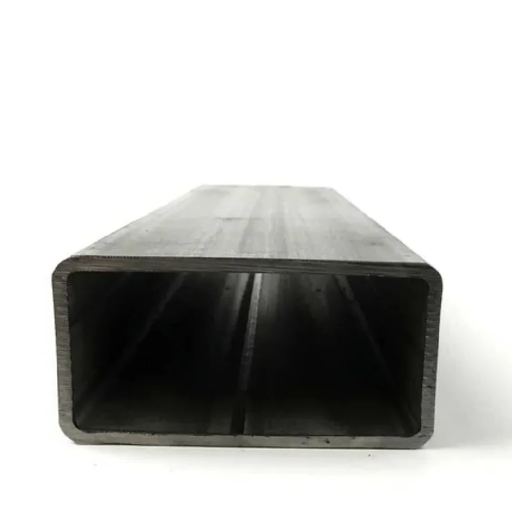

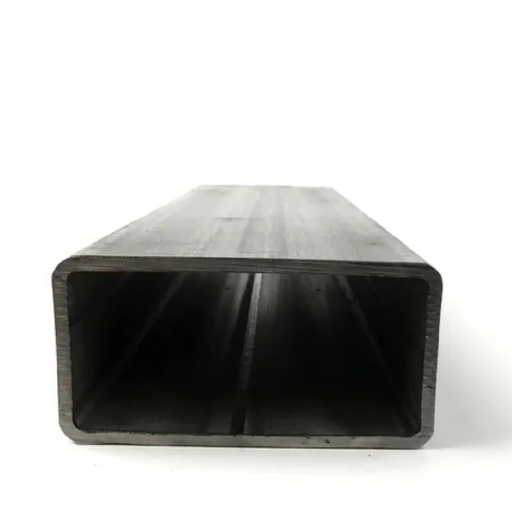

Welded and Seamless Rectangular Steel Tubing

2025-10-20 16:10:47

Selecting the right materials is essential in the construction, manufacturing, and many other sectors to ensure the project success. Rectangular steel tubing, which is obtainable in welded and seamless forms, is a very adaptable and strong option across various applications. However, the question arises as to what the differences between these two types of tubing are? Moreover, how do their specifications affect performance and appropriateness for particular projects? This article takes an in-depth look at welded and seamless rectangular steel tubing, emphasizing their different characteristics, benefits, and typical applications. It doesn't matter whether you're an experienced expert or a newcomer; this manual will provide you with the valuable information you need to make the right choices regarding your steel tubing needs.

Introduction to Steel Rectangular Tubing

Steel rectangular tubing is a hardwearing and versatile material that is extensively used in the construction, manufacturing, and engineering industries. Its cross-section is a rectangle which gives it great strength and stability. The steel rectangular tubing can be divided into two major categories: welded and seamless. Welded tubing is produced by the joining of steel plates or coils at the seam, hence it is cheaper and suitable for most common applications. Conversely, seamless tubing, despite being more difficult to manufacture, is formed without a weld seam and therefore, besides being stronger and less susceptible to pressure, is also very well suited for high-performance or demanding applications. Ultimately, the selection of one over the other boils down to the specific project requirements, such as load capacity, budget, and other environmental factors.

What is Steel Rectangular Tubing?

Steel rectangular tubing is a hollow structural section with a rectangular cross-section that is very versatile, and it is widely used in construction, manufacturing, and industrial applications for its strength, durability, and ability to adapt to different kinds of load-bearing requirements.

Difference Between Welded and Seamless Tubing

It is of utmost importance to comprehend the disparities in between the welded and seamless steel tubing before making such a choice, not only concerning their manufacturing processes but also their properties and typical applications. The differences are summed up in the following five points.

Manufacturing Process

Welded Tubing: The process consists of taking a flat sheet of steel, rolling it into a tube shape, and then welding the edges together along a line that runs the length of the tube.

Seamless Tubing: It is made by pushing a solid steel billet through a die that hollows it out, leaving no seams or welds.

Strength and Durability

Welded Tubing: The weld can be regarded as a structural weakness, but this has, however, been greatly minimized through the use of advanced welding techniques.

Seamless Tubing: They are typically regarded as stronger and more durable because of the absence of a seam which is the main reason why they are used in high-pressure applications.

Surface Finish

Welded Tubing: Usually, it comes with weld lines that may necessitate extra finishing for aesthetics.

Seamless Tubing: Has a smooth and even surface with no weld marks thus it is more aesthetically appealing for some applications.

Cost

Welded Tubing: Generally more economical as the production process is simpler and requires less raw material.

Seamless Tubing: Priced higher due to the more complex manufacturing process and the accuracy required being great.

Applications

Welded Tubing: It is often applied in projects with moderate strength requirements like handrails, fences, and low-pressure structural applications.

Seamless Tubing: It is the choice for critical applications where high strength and reliability are the foremost conditions such as in the automotive and aerospace industries, or in oil and gas drilling.

By knowing these differences, the engineers and designers are able to select the tubing that best fits their project requirements.

Specifications of Welded and Seamless Tubing

When one looks at welded tubing and seamless tubing, the comparison of their specifications points out the advantages and usages of each variety. A thorough examination of their traits and critical factors is provided below:

Welded Tubing

Manufacturing Process:

The steel strip is rolled up and the seam is welded to make the tube.

Laser Welding and TIG Welding are some of the advanced welding techniques used which guarantee very few defects in the seam.

Dimensional Precision:

Due to controlling the rolling process for the initial rolling, it provides excellent dimensional accuracy.

The standard sizes most often are ASTM A249 or A269 tolerances for welded tubing.

Surface Finish:

Welded tubing is finished in a way that it frequently gets a smoother external surface, i.e., there is less roughness.

Commonly used finishes are brushed, polished, or mill finish.

Strength and Performance:

The heat affected zone where the original weld was located will lower the strength a bit.

If there is no seam, seamless tubing has increased integrity and strength making it suitable for high-pressure areas where leaks cannot be tolerated.

Cost:

Because welded tubing is a simpler type of manufacturing, it is usually cheaper than seamless tubing.

Applications such as handrails, HVAC systems, decorative purposes, process piping, and structural components in low-stress environments are the areas where welded tubing is most commonly used.

Seamless Tubing

Manufacturing Process:

A solid rod of steel or other material is pierced, and a hollow tube is created, making it the tubing with no weld seam.

Different methods include extrusion and rotary piercing.

Dimensional Precision:

Seamless tubing is known to be accurate with diameters less than 2 inches.

It meets the ASTM A213 standard for high-temperature resistance.

Strength and Durability:

Seamless tubing is characterized by being of good integrity and strength since it is free of seams.

It is the perfect usage under environments with high pressure where leaking is unacceptable.

Surface Finish:

The internal and external surfaces may be required to be finished further depending on the application.

Common Applications:

Components for aerospace, hydraulic systems, oil & gas pipelines, and other high-pressure equipment.

Cost:

Because of the complicated manufacturing process and higher material demands, seamless tubing costs more than welded tubing.

Data Comparison Example:

Specification | Welded Tubing | Seamless Tubing |

|---|---|---|

Manufacturing Process | Rolling and welding | Extrusion or rotary piercing |

Strength | Moderate, seam weaker than tube body | High, no seam for added reliability |

Pressure Tolerance | Moderate | High |

Dimensional Accuracy | Good, consistent along the tube length | Excellent, particularly for small diameters |

Cost | Lower cost | Higher cost |

Understanding the technical specifications and usability of welded versus seamless tubing is essential for selecting the right material according to project demands. Both types excel in specific areas, emphasizing the importance of matching tubing properties to application requirements.

Common Sizes and Shapes

When choosing tubing, the selection is based on a myriad of sizes and forms so as to cover the vast usage of different industries. Generally, manufacturers do offer tubes in standard sizes, where the outer diameters (OD) vary from 1/8 inch (3.2 mm) up to 8 inches (203.2 mm) and even more for certain uses. The thickness of walls also differs, as there are super thin-walled options for projects that are sensitive to weight, heavy-walled tubes, and those that can withstand high-pressure applications.

Forms

The most common and flexible type is the round tubing, usually found in structural, mechanical, and fluid transport applications.

Square and rectangular tubes are used a lot for frames, supports, and machinery that are meant to share weight evenly. The strength of these shapes is the same in every direction, and at the same time, they are more convenient to connect and put together.

It is rare to find oval and elliptical pipes, yet their contribution is irreplaceable when it comes to aerodynamic designs and artistic applications. They bring in sleekness and modernization and at the same time do not compromise on stability.

Also possible are the custom shapes, which can be made through special manufacturing processes for niche or proprietary markets.

The standards for tubing sizes usually go hand in hand with the industry rules such as ASTM, ASME, or ISO specs, which make the tubing compatible with and consistent in performance across all applications. Some of the famous ones are ASTM A213 for the production of seamless stainless steel tubing and ASTM A500 for structural steel tubes. A correct choice of tubing size and shape according to the application's load requirements, design constraints, and environmental considerations guarantees both performance and longevity.

Wall Thickness and Diameter Considerations

Wall thickness and diameter are two very important factors that have a direct influence on the performance, durability, and applicability of the tubing. The right choice of these parameters is a guarantee that the tube will take the intended load, pressure, and environmental conditions. The following are five key details and data points about wall thickness and diameter:

Inner Diameter (ID) and Outer Diameter (OD): The wall thickness is determined by the difference between these two measurements. Accurate dimensions are very important in fluid flow applications where very precise internal space is required.

Wall Thickness Tolerance: Manufacturing processes may lead to small differences, thus it is vital to take the standard tolerance range specified by standards like ASTM or ISO into account.

Pressure Ratings: Thicker walls usually permit higher pressure ratings. Depending on the application, the tubing must resist the maximum operating pressures without any deformations or failures.

Weight Considerations: Heavier tubing because of thicker walls may contribute extra weight that is not needed in the structure or system, thus, affecting material choice and overall design efficiency.

Corrosion Allowance: In case of corrosive environments, it is usually the case to pick a thicker wall to account for the loss of material and to extend the service life of the tube.

If all these factors are taken into account, the tubing will be perfect for its intended application, thereby providing both safety and efficiency.

Applications of Rectangular Steel Tubing

Rectangular steel tubing is a powerful material that is able to withstand very heavy loads and at the same time, can be modified to suit different requirements, which is why it finds use in a number of industries. Here are five areas where rectangular steel tubing is most commonly applied:

Structural Support in Construction:

Rectangular steel tubing is widely applied in the construction of structures like buildings, bridges, and other infrastructure. Its a high strength-to-weight ratio that allows it to be used in building structures like frameworks and trusses to mention just a few.

Manufacturing of Furniture:

The durability and aesthetic appeal of rectangular steel tubing make it a preferred choice in the creation of furniture such as tables, chairs, and shelving units. Moreover, its surface is smooth and uniform, making it easy to weld and finish.

Automotive Industry:

Chassis, roll cages, and strengthening parts are just some of the areas where rectangular steel tubing is used in the automotive industry. Its capacity to hold up against high stress and impact guarantees safe and long-lasting vehicles.

Industrial Equipment and Machinery:

Rectangular steel tubing is one of the industry's go-to materials for the production of machinery frames, conveyor systems, and equipment components. Its structural rigidity and resistance to wearing out quickly are just some of the factors behind its widespread use in these applications.

Agricultural Frameworks:

It is customary to see rectangular steel tubing in agriculture used in building barns, greenhouses, fencing, and irrigation systems. Its power to survive in a variety of environmental conditions contributes greatly to its long-lasting and trustworthy service.

Structural Applications in Construction

Due to its strength, durability, and versatility, rectangular steel tubing is a cornerstone material in the construction industry. Below are five principal structural uses of rectangular steel tubing that can be found in the everyday practice of designers and builders:

Building Columns and Beams: The sturdiness of rectangular steel tubing has made it a prime candidate for the construction of various types of building structures columns and beams such as residential, commercial, and industrial. Ensures that stability is obtained and supports the loads in vertical and horizontal directions efficiently.

Bridges and Overpasses: Tubular steel in rectangular form has been a common material in the making of bridges and overpasses construction. The lighter but high tensile strength of the tubing together with the creativity and durability of the design allow to have the material costs reduced at the same time.

Trusses and Roof Frameworks: The rectangular shaped steel tubing has a good support capacity for trusses and roof systems; the one in it that bends and consequently finds it hard to resist load from the heavy materials used for roofing or from environmental loads makes it prefer infrastructure that lasts long.

Railings and Staircases: Strong and lasting railings and staircases can be easily made from the rectangular steel tubing. Besides being a bit of cutting and welding, this tubing gets the desired aesthetic and functional requirements of contemporary architecture.

High-Rise Buildings: The rectangular steel tubing utilized in the high-rise buildings' framework is crucial for preventing and withstanding the forces of wind, earth tremors, and other stresses. Its flexibility opens up new concepts in design that are not only space-efficient but also preserve the integrity of the structure.

Mechanical Applications and Uses

The rectangular steel tubing gets utilized in a lot of mechanical applications and its strength, versatility, and precision are the main reasons of its usage in such a variety of applications. Five key uses in the field of mechanics are given below:

Automotive Frames: The rectangular steel tubing is the backbone of the automotive frames and the chassis. The support it provides is both strong and lightweight enough to improve the vehicle's safety and durability.

Industrial Machinery: Heavy-duty and continuous operation are the two most demanding scenarios in which rectangular steel tubing serves as a Reliable and Stable support for the construction of industrial machines.

Robotics and Automation: Due to the high precision of the tubing and its capacity to tolerate the repetitive mechanical force, it becomes the major part of the robotic structures and the automated systems.

Conveyor Systems: Steel rectangular tubing is a key player when it comes to conveyor systems as the main part that supports and efficiently transports large loads of materials across the production lines.

Agricultural Equipment: Besides these, the tubing is also a very important element in farm machinery such as tractors, harvesters, and irrigation systems where resilience and precise design attributes are required in the environments that are hard to work in.

Conclusion

The rectangular steel tubing has a very important part in many different industries thanks to its versatility, strength, and durability. The construction, manufacturing, transportation, and agriculture are the main areas of its application proving its reliability and adaptability in the most difficult conditions. The structural integrity and performance consistency provided by rectangular steel tubing make it a very important material still in diverse sectors.

Summary of Key Points

Versatility Across Industries

The rectangular steel tubing's design is one of the factors that make it a widely used material in the construction, manufacturing, transportation and agricultural industries. The ability to alter its sizes and wall thickness, among other things, has made it still very functional for different purposes. For example, it is used in building materials and support in construction, while it is also common in agricultural equipment and storage systems.

Structural Strength and Durability

Rectangular steel tubing has gained its popularity due to its long-lasting reliability and high tensile strength. The data shows that the yield strengths of steel tubes can be as high as 80,000 psi or as low as 40,000 psi, depending on their type. This makes it a primary selection for critical applications that need load-bearing support.

Corrosion Resistance

Rectangular steel tubing treated with protective coatings or galvanization becomes strongly resistant to rust and environmental wear. Studies found that galvanized steel can last even up to 50 years in dry environments or about 25 years in less favorable ones if proper maintenance is done, thereby making it cost-effective over time.

Lightweight yet High Performance

Steel tubing's upper hand over other materials like concrete or wood in terms of strength-to-weight ratio makes it an optimal choice for designs needing less weight without sacrificing structural integrity. Thus, for instance, thin-walled rectangular tubing, due to its lightweight properties and durability, is often used in bicycle frames.

Sustainability and Recycling

Steel is one of the most recycled and reused materials all around the globe. As per the recent figures released by the World Steel Association, almost 90% of steel materials are recovered in developed countries, which, in turn, makes rectangular steel tubing an Eco-friendly product. Its high recyclability is a way of minimizing industrial waste and simultaneously meeting the sustainability criteria.

Rectangular steel tubing, with its consistent performance and versatility, is still the material of choice in supporting the innovative design and technological progress in diverse industries.

Future Trends in Rectangular Steel Tubing

The coming years for rectangular steel tubing are looking great as it will be in sync with the advancements in technology, sustainability, and innovative engineering practices. One major trend going on is the rising request for high-strength and light tubing solutions. The carbon footprint reduction in buildings and their components is the reason for the mentioned trend to be in the steel industry's attention. For example, the strength of high-strength low-alloy (HSLA) steel is gaining more users among the manufacturers due to its less weight and more strength than the traditional materials used.

Care for the environment and the planet is getting more and more attention. The manufacturers are up to their game in green production processes as the need to reduce the carbon footprints has become a global concern. The steel producing companies are adopting electric arc furnaces (EAFs) instead of using majestic blast ones as the latter is one of the biggest contributors to the overall greenhouse gas emissions. The latest information by the steel companies that use EAF operations says they can lessen their CO2 emissions by as much as 75%. In addition, the already existing circular economy practices, which state that once the steel gets recycled, it is not made into any product, but rather it is made into new products, are likely to get bigger. Actually, it is already the 70% of steel that is produced globally and is made from recycled materials.

The rectangular steel tube is getting an upgrade with the use of the latest technology like the smart coatings. The coatings can increase the resistance to corrosion and at the same time, they can assist in monitoring the health of the structure by indicating the stress or damage in real-time. The above-mentioned innovations would be very useful in the infrastructure as the concurrent factors of durability and safety are very important.

Finally, the trends of customization and precision engineering are becoming prominent. The modern manufacturing technologies like laser welding and 3D printing not only enable greater customization to be done on the steel tubing to satisfy various specifications but also take care of the material waste and tolerance thereby perfecting the industries lik e robotics and renewable energy systems that only want the highest precision.

With the development of these trends, the use of high-performance materials and creative technologies will guarantee that rectangular steel tubing remains a reliable partner in the quick-changing needs of different sectors as it will also keep sustainability and efficiency at its core.

Tags: Welded and Seamless Rectangular Steel Tubing