-

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

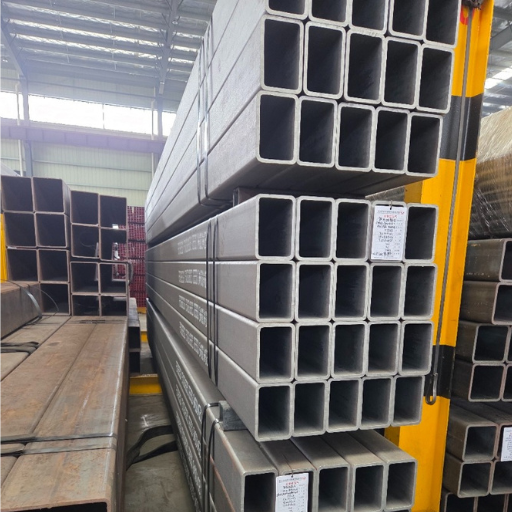

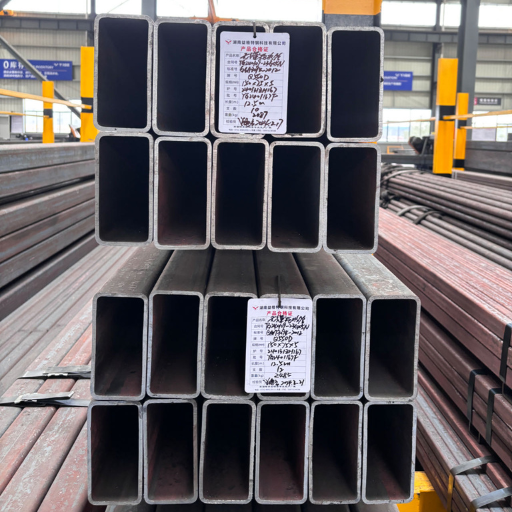

Seamless Square Pipe: Understanding Square Steel Tubing and Its Applications

2025-10-21 14:04:45

Square steel tubing, which is sometimes simply called seamless square pipe, is a very important and versatile feature of today's construction, manufacturing, and engineering applications among others. Its strength, long-life, and even shape in combination place it on top of the list among materials for structural frameworks, load-bearing systems, and precision fabrication. The intention of this blog post is to present an in-depth exploration of square steel tubing that will bring to light the beginning of the manufacturing processes, its main characteristics, and the use of the material in various industries. No matter whether you are an engineer, an architect, or a professional from the industry wanting to improve the efficiency of the design or the performance of the material, this guide will be comprehensive and will provide you with important knowledge that will help you understand the benefits and multipurpose nature of seamless square pipe.

Overview of Seamless Square Pipes

Seamless square pipes are categorized under hollow structural sections (HSS) and are recognized for their equal strength properties and large load-bearing capacity. These pipes are produced with no welded joints, thus they have better structural integrity and resistance to pressure, which makes them perfect for crucial applications. The hot or cold rolling processes are the most common methods for their production, and they have a wide range of applications in the construction, automotive, and manufacturing sectors. Among the primary advantages are the long life, the exactness of measures, and the multiple uses, which are the reasons why seamless square pipes are regarded as very trustworthy and effective in both structural and mechanical applications.

Definition of Seamless Square Tubing

Seamless square tubing stands as a hollow structural section that comes without welded seams, maintaining uniformity and getting rid of the common weaknesses that arise from welded joints. The making of seamless square tubes happens through a complicated process like extrusion or rotary piercing, where raw steel billets undergo heating, then, they are forced through a die and finally cut into a tube before being squared to the envisaged dimensions.

The tubes thus formed are praised for their tensile strength, accurate dimensions, and ability to withstand very high pressures and extreme conditions. They come in a vast array of sizes starting from small dimensions like 10mm x 10mm with a wall thickness of 1mm, to large tubes like 500mm x 500mm with wall thicknesses of over 20mm, thereby, meeting a wide range of mechanical and structural demands. Generally, the material composition consists of alloys like carbon steel, stainless steel or even high-strength low-alloy steel, thus, making it suitable for the respective application in terms of performance.

Additionally, modern technology in seamless square tubing production has resulted in the tolerances being much tighter than before, better surface finishes, and much higher corrosion resistance, particularly because of precision cold drawing and advanced heat treatments. These innovations make seamless square tubing a must-have in various industries like aerospace, energy, automotive, and heavy machinery, where high performance and reliability are non-negotiable.

Recent surveys and market studies show a trend of increasing demand for seamless square tubing, with an annual market growth rate of 5.2% CAGR for the years 2023 to 2030 predicted, mainly due to more infrastructure projects being carried out and the continuing development of engineering. The combination of excellent material properties and many uses makes seamless square tubing what can be termed as a major player in the modern-day industrial standards.

Key Characteristics of Square Steel Tubes

High Strength-to-Weight Ratio

The strength-to-weight ratio of square steel tubes is remarkable, thus they can be employed in various fields of use, such as structures that need considerable strength but light materials. For example, structural frameworks are supported by this property through the safety of the structure without the issue of excessive load stress to the structure.

Corrosion Resistance

The advanced coating techniques like galvanization or powder coating will usually boost the corrosion resistance of square steel tubes. They can be very durable depending on the material grade, as they are resistant to very harsh conditions including moisture, chemicals, and extreme weather.

Dimensional Precision

Seamless square tubing is produced to very precise dimensional tolerances, often being compliant with the industry standards such as ASTM A500. This degree of precision not only allows the manufacturing of many parts from one single raw material but also reduces the cost for the user, since less material is needed at the end of the process, which is also the case for the entire application engineering and construction.

Versatile Cross-Sectional Design

The square cross-sectional design, on the one hand, allows for even load distribution and better resistance against bending and cracking, on the other hand. This makes the square steel tube an especially good choice in the construction of load-bearing structures where an ideal combination of durability and utility is required.

Thermal and Mechanical Stability

Square steel tubes can be subjected to high temperatures and mechanical stress without giving in to their structural integrity. According to tests performed, high-grade steel types can survive with thermal variations from -50°F all the way to 1200°F, thus they are the best for industrial processes, pipelines, and energy structures.

Manufacturing Process of Seamless Square Pipes

Seamless square pipe manufacturing is a meticulous process made up of a sequence of operations that are strict and highly controlled to prevent any problems and assure the pipes' durability, dimensional accuracy, and structural integrity. Here's a quick overview of the main stages in the production process:

Selection of Raw Material

The starting material for the production is high-quality steel billets or ingots. The composition of these materials is usually either carbon steel or alloy steel, with certain grades like ASTM A106 or ASTM A500 being regularly used in high-performance applications.

Heating and Piercing

The steel billets are raised to a temperature of about 2200°F in a rotary hearth furnace for the necessary plasticity to be achieved. The billets are then pierced with a mandrel or a piercing mill to form a hollow shell thus creating the initial shape of the seamless pipe.

Rolling and Shaping

The hollow shell is rolled in a continuous rolling mill or a stretch reduction mill to its final dimension of thickness and square shape. The process makes use of advanced roll designs that allow the wall thickness and corner dimension to be kept within a 0.5% tolerance range.

Heat Treatment

The mechanical properties required are obtained through heat treatment processes such as normalization, quenching, and tempering. Quenching is usually done at 1650°F and then the pipes are tempered at 800°F to 1200°F to make them tougher and more ductile.

Surface Finishing and Testing

The surface of the pipes is treated by either sandblasting or pickling in order to have a good smooth finish as the last operation. Then, nondestructive testing methods, such as ultrasonic testing (UT) and eddy current testing (ECT), are applied to every pipe for the detection of internal or surface flaws. The pipes are also subjected to hydrostatic testing at a pressure of up to 3,000 psi to ensure their leakproof quality.

Consequently, seamless square pipes have passed the most rigorous quality checks and are now ready for use in numerous applications such as construction, automotive, and energy distribution as their thorough industry standards have been met.

Production Techniques for Steel Square Tubes

Steel square tube production includes complicated and executed with precision methods to guarantee quality and longevity. In manufacturing, the following are the five major production techniques, which are applied by the industry:

Hot Rolling

Hot rolling consists of heating slabs or billets of steel beyond their recrystallization temperature and rolling them out between rollers until the desired thickness and shape are reached. The steel thus produced is strong and has a homogeneous structure that is able to endure the most demanding applications.

Cold Forming

Cold forming is a process done at room temperature using pressing or rolling to shape the steel tubes out of pre-processed steel coils or strips. The process gives rise to the cleaner finish, better dimensional accuracy, and greater mechanical properties resulting from strain hardening.

Welding

Welding is an important step in the making of steel square tubes from strips. The method of high-frequency electric-resistance welding (ERW) is widely used to bond the edges of the strips, and thus a rigid bond is achieved. The joined part is then subjected to a heat treatment that improves strength and evenness.

Seamless Tubing

Seamless tubes of steel are made by piercing solid billets of steel and then pulling them into a hollow shape. The process does away with welding seams and enhances the tubes' strength, thus making them suitable for applications where pressure or loads are high.

Galvanizing

Galvanizing is the technique whereby zinc, which is a protective material, is applied to steel tubes to stop them from rusting. Hot-dip galvanizing, where the tubes are dipped in molten zinc, or electro-galvanizing, which uses an electric current to attach the zinc layer, are two methods employed in this process.

The combination of these production methods guarantees that steel square tubes reach the tough performance and quality standards that are necessary in multiple industries.

Comparison with Welded Square Tubing

Parameter | Seamless Square Pipe | Welded Square Tubing |

|---|---|---|

Manufacturing Process | Extruded from solid billet | Rolled and welded from steel strip |

Strength | Higher due to no weld seams | Lower, weld seams may weaken structure |

Corrosion Resistance | Excellent, no weak points | Good, but weld seams may corrode |

Cost | Higher due to complex process | Lower, simpler manufacturing |

Size Availability | Limited, smaller size range | Wider range of sizes and shapes |

Durability | Superior for high-pressure applications | Suitable for general-purpose applications |

Applications | High-pressure, critical uses (e.g., oil, gas) | Construction, machinery, general plumbing |

Surface Finish | Smooth, uniform | Visible or smoothed weld seams |

Production Speed | Slower due to multiple steps | Faster, continuous process |

Cost-Effectiveness | Less cost-effective for non-critical uses | More cost-effective for general applications |

Advantages of Using Seamless Square Pipes

Exceptional Structural Integrity

Seamless square pipes are produced without any welds, which means that the whole piece has the same strength and depending on the amount of people holding it. Therefore, it's not possible for the material to get under stress, thus making them suitable for high-pressure and high-load applications in such industries as construction and aerospace where the materials are required to react to the environment without failure.

Superior Resistance to Corrosion and Cracking

It is the fact that seamless square pipes do not have welded joints that contributes to their superior performance in the area of corrosion and stress cracking. Hence, they are absolutely perfect for the environments where there is a lot of moisture, chemicals, or extreme temperatures.

Enhanced Dimensional Accuracy

The manufacturing process for seamless pipes is such that there is virtually no space for error and the dimensions are very accurately set. Such precision of the outer diameter and wall thickness allows for easy assembly and alignment in the peak manufacturing engineering applications, and modification of the parts will not be necessary and the strict specifications will still be fully adhered to.

Higher Pressure-Bearing Capacity

Pipes made of seamless square are able to take more pressures than pipe of welded type in their internal and external parts. Research suggests that seam pipes can take up 20-30 percent more pressure in some uses, hence, it is indispensable in oil, gas and hydraulic systems.

Longer Service Life

The strength and adaptability of seamless square pipes are the factors that lead to the elongation of their operational life. Their high resistance to degrading, coupled with low maintenance requirement, make them a money-saving option in the long run, especially in high-demand environments.

Durability and Strength of Steel Tubing

High Tensile Strength

Steel tubing's tensile strength is truly amazing and its common grades like ASTM A500 and ASTM A513 provide a range of 400-550 MPa that is pretty much standard. Thus, the material can work where there are a lot of loads and high-pressure cases.

Corrosion Resistance

On the choice of coating or alloy composition, steel tubing can give big corrosion resistance. Galvanized steel tubes, for example, do not rust even when they are in contact with the elements, and the stainless steel grades such as 304 or 316 provide even more resistance in the most aggressive chemical environments.

Impact Resistance

Steel tubing comes with great impact toughness and can even hold up under low-temperature applications. This quality in particular is of great importance in construction and transport industries as it relates to the high-stress situation of the structure.

Thermal Stability

Steel tubing is able to maintain its structural integrity throughout a wide range of temperatures. Alloy steel tubing, for instance, can take up to 870°C (1600°F) high temperatures without becoming significantly deformed making it applicable for the sectors of heat exchangers and boilers.

Fatigue Strength

Steel tubing under cyclic loading conditions delivers high fatigue strength that is exceptionally good which assures reliable performance in the likes of automotive parts or heavy machinery applications. This factor of durability also minimizes the chances of failure even though the stress cycles are repeated.

Corrosion Resistance in Stainless Steel Tubes

Corrosion resistance is one of the most remarkable properties of stainless steel tubes, which is mainly attributed to the use of chromium that forms a passive oxide layer on the metal surface. This property makes stainless steel tubes capable of being used in the most demanding environments like marine, industrial, and chemical processing applications to name a few. Below are five factors that lead to the corrosion resistance of stainless steel tubes:

Chromium Content

Chromium, which is usually about 10.5% of stainless steel at least, combines with oxygen to form a passive oxide layer. This oxide works as a shield, which not only protects the metal from further oxidation but also resists general corrosion in most environmental conditions. The more chromium content, the better the corrosion resistance.

Molybdenum Addition

Alloying of stainless steel with molybdenum enhances its pitting and crevice corrosion resistance; this is the case for grades 316 and 317. Such properties become a great asset in environments rich in chlorides, e.g. seawater or exposure to industrial chemicals.

Nickel Enrichment

Austenitic stainless steels, which are the ones to have nickel usually, possess excellent resistance to corrosion in acidic and alkaline conditions. Nickel also increases the tube's durability when subjected to extreme environmental conditions.

Preventing Intergranular Corrosion

Using low-carbon stainless steel grades (marked with "L," e.g. 304L and 316L) reduces the likelihood of intergranular corrosion. These grades provide more time for corrosive attacks in harsh environments by controlling the precipitation of carbides during welding or heat treatment.

Resistance to Stress Corrosion Cracking (SCC)

Stainless steel tubes, especially duplex and super duplex grades, do not suffer from stress corrosion cracking even under the combination of chlorides and high temperature conditions. The good microstructure of these alloys corresponds to high mechanical strength and stress tolerance.

These factors exhibit the ability and dependency of stainless steel tubing to conserve its integrity and performance during the corrosion process.

Common Applications and Industries

The use of stainless steel tubing is very common in many different sectors mainly because of its great resistance to corrosion, good strength, and flexibility. The following are some of the main applications and industries that make use of it:

1. Oil and Gas Industry

Stainless steel tubing, in particular duplex and super duplex grades, is widely used in subsea pipelines, downhole equipment, and flowlines because of its resistance to chloride-induced stress corrosion cracking (SCC) and localized corrosion. A 2023 report by Market Research Future states that the global oil and gas stainless steel tube market will grow with a compound annual growth rate (CAGR) of 5.6% up to 2030, as a result of the increase in offshore exploration and energy consumption.

2. Chemical Processing

Stainless steel tubes are extensively used by the chemical industry for transporting even the most reactive or corrosive chemicals. Grades like 316L and super austenitic alloys are the materials of choice for processes involving both very hot and aggressive media in heat exchangers, reactors, and piping systems. The use of these materials not only prevents contamination but also prolongs the life of the equipment.

3. Food and Beverage Industry

Foods and drinks that meet the highest hygiene standards need the help of perfectly smooth stainless steel tubing. As a non-reactive surface that is easy to clean, the tubes are extensively used in the equipment of pasteurizers, conveyors, and fluid handling systems. The Food Processing Institute states that industrial stainless steel tubing is being increasingly adopted in the dairy, brewing, and confectionery sectors where compliance with FDA and HACCP regulations is a must.

4. Aerospace and Automotive Sectors

The combination of lightweight and high-strength in certain grades of stainless steel tubing has led to their increasing use in the aerospace and automotive industry. Aerospace hydraulic systems and automotive exhaust systems use seamless stainless steel tubes, which can withstand high temperatures and resist oxidation, to guarantee durability and reduced weight. These applications show how important material engineers are in the transportation industry.

5. Medical and Pharmaceutical Industry

Stainless steel tubing is one of the main materials in making medical devices, surgical instruments, and pharmaceutical processes. Its compatibility with the human body and non-toxicity make it the best option in applications like hypodermic needles, implantable devices, and sterile transfer lines. New reports are predicting that the medical-grade stainless steel tube market will grow significantly, particularly with the improvement of minimally invasive surgical techniques.

6. Power Generation

Stainless steel tubing is utilized by the energy sector in boilers, heat exchangers, and condensers in both fossil fuel and nuclear power plants. The advanced stainless steels can survive harsh conditions, such as those hot and high-pressure environments, making them vital in these areas. The move towards eco-friendly energy sources has led to stainless steel tubes being used more in solar thermal systems and wind energy.

The range of applications for stainless steel tubing is vast and features of it show its essential position in modern infrastructure and technology. This quality also means that the material will continue to undergo innovations and experience growth in its application over the years.

Construction Uses of Square Steel Tubing

Square steel tubing is a material that has a lot of different uses and is very durable. It is widely used in the construction industry because of its strength, lack of variation and easiness to manufacture. Its applications are not limited to structural and architectural purposes but rather a secure and dependable construction solution for the demanding needs of modern society. Below is a thorough list of five main uses of square steel tubing in the construction field:

Structural Frameworks

Square steel tubing is often used as core material in the structural frameworks of various constructions like buildings, bridges, and industrial facilities. The combination of high load-bearing capacity and resistance to torsion makes it a perfect choice for the construction of strong and stable frameworks.

Steel Trusses and Roofs

The uniform cross-section and excellent rigidity of square steel tubing have led to its common use in trusses and roofing systems. By doing so, it will not only be a reliable but also a large weight evenly distributing support across large spans which the structure will maintain.

Fencing and Railings

Square tubing is extensively used for building fences, railings, and safety barriers. Its stark geometric lines as well as its ability to endure environmental stresses are the reasons why it is a favorite choice in both functional and aesthetic applications.

Columns and Beams

The astonishing compressive and tensile strength of square steel tubing enables it to perform well as columns and beams in different kinds of structures. It is particularly useful in projects that need the use of lightweight yet sturdy parts, such as multi-story buildings.

Scaffolding Systems

Square steel tubing is the main material of designing scaffolding systems which are necessary during construction and maintenance processes. The uniform dimensions of the tubing and their ability to interconnect securely, provide stability and safety for workers at heights.

The above applications indicate the fundamental part of square steel tubing that comes with the construction of structures having different designs, durability, and appealing looks as well. Its capability of being engineered to specific demands makes it still relevant to the current construction practices.

Industrial Applications of Seamless Square Pipes

Industries that demand strength, durability, and very tight dimensional tolerances use seamless square pipes as one of their key components. The seamless construction of these pipes completely eliminates the problem of weak points that would be otherwise caused by welding, hence, making them very reliable for critical applications. Here are the five major industrial uses of seamless square pipes:

Oil and Gas Industry

Seamless square pipes are used in pipelines, structural supports, and offshore installations because of their property to resist high pressure and withstand even the most unfavorable acidic and alkaline conditions. The exactness of their dimensions makes it very easy to incorporate them into the complex infrastructures, thus, enhancing the reliability of the whole system.

Automotive and Transportation

These pipes are critical in the production of vehicle frames, chassis, and other vital parts. The pipes' high tensile strength and stress resistance are among the factors that contribute to the safety and longevity of automotive structures.

Construction and Infrastructure

Seamless square pipes are a must-have material in the construction of any type of building, be it commercial, industrial, or residential. They are commonly used in the construction of load-bearing columns, steel frameworks, and safety railings where strength and uniformity are the top-most priorities.

Aerospace Industry

The aerospace industry uses seamless square pipes for aircraft frames, space exploration vehicles, and support systems. The pipes' strong but light properties are what makes them satisfy the demanding criteria of the aerospace industry.

Mechanical and Hydraulic Systems

These pipes are vital in hydraulic machines, pneumatic systems, and cooling circuits in factories. The pipes' highly accurate interior and ability to withstand fluid and gas pressures guarantee the best possible efficiency of the system.

The remarkable qualities of seamless square pipes which include flexibility, durability, and performance make them a staple material in these and other industrial sectors. The ongoing technical innovation in steel production processes will soon allow these pipes to be used in more and more new technology applications.

Tags: Seamless Square Pipe