-

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

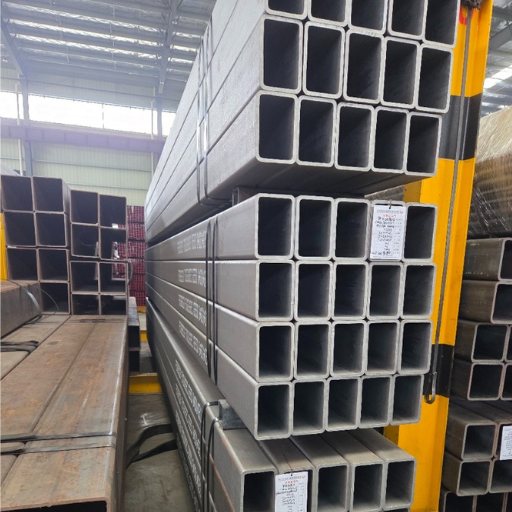

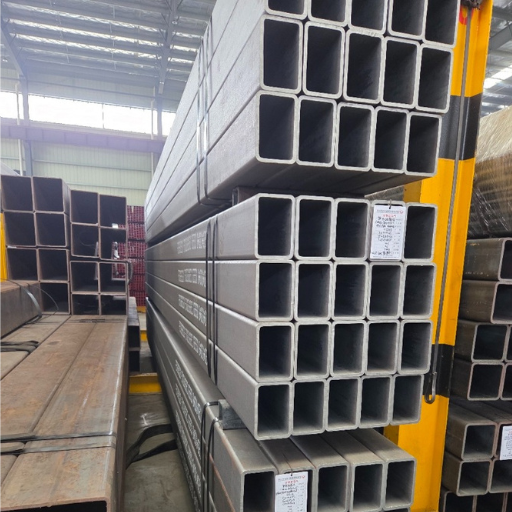

Seamless Square Steel Pipe: Understanding Its Applications and Manufacturing

2025-10-24 14:58:29

Seamless square steel pipes are among the most essential solutions in construction and manufacturing for their versatility and reliability. The pipes are recognized for their main characteristics —strength, durability, and a smooth aesthetic —and play a critical role. —strength, durability, and a smooth aesthetic — Extrusion or hot rolling is used in manufacturing to form steel broad applications into a square shape without joints or seams. , Essential roles in different industries; their usage ranges from the construction of giant infrastructures to aiding cutting-edge machinery, and the applications are numerous, as well as their effect. The article will take readers on a journey through the vertical and horizontal applications of seamless square steel pipes, explaining their manufacturing process and why they are the top choice for engineers and architects. Professionals working in the industry or people curious about these materials can learn about the production process and the extensive use of seamless square steel pipes in this article. So, get ready to find out how seamless square steel pipes are already essential in the highly competitive, accuracy-driven environment of the 21st century.

Overview of Seamless Square Steel Pipes

Seamless square steel pipes are hollow structural sections that are produced without welded seams and thus have the same strength and durability throughout their length. Extrusion or hot rolling is used in manufacturing to form steel broad applications into a square shape without joints or seams. These pipes are valued for their strength, high-pressure resistance, and wide range of applications. They have broad applications in construction, automotive, and industrial sectors, where they provide a tough, reliable solution for projects that require both quality and strength.

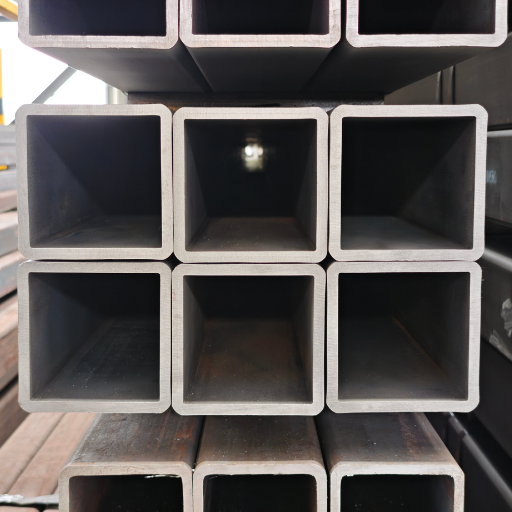

Definition and Unique Characteristics

Seamless square steel pipes are steel tubing with no joints or welds throughout their structure; thus, they are powerful and versatile. These pipes are manufactured using seamless processes, namely hot-rolling or cold-drawing, which ensure uniform thickness and composition throughout.

The fact that seamless square steel pipes are able to bear high-pressure environments without leaking or collapsing risk is one of the main benefits of these pipes. They are, for instance, most preferred in the oil and gas transportation, heavy machinery, and construction sectors. Recent studies have highlighted their tensile strength, which typically ranges from 400 MPa to 700 MPa, depending on the steel grade used. Thus, they can be considered ideal candidates for demanding applications that require both durability and high performance.

Moreover, seamless square steel pipes can be made to exhibit even better corrosion resistance when coated or alloyed with materials such as galvanized steel or stainless steel grades. Besides, their precise measurements enable their use in industries that demand tight tolerances, such as automotive and aerospace. The global demand for seamless square steel pipes is expected to grow steadily, with a CAGR of more than 5% from 2023 to 2030, driven by demand from the infrastructure and energy sectors, according to market research.

The distinctive characteristics of seamless square steel pipes make them not only a practical option but also an enduring solution for a vast variety of industrial and commercial applications worldwide.

Comparison with Other Types of Pipes

Key Point | Seamless Square Steel Pipe | Welded Square Steel Pipe |

|---|---|---|

Manufacturing Process | Extrusion, no welds | Welding steel plates or strips |

Strength | Higher, uniform composition | Lower, welds may weaken structure |

Corrosion Resistance | Better due to no seams | Moderate, welds may corrode |

Dimensional Accuracy | High precision | Moderate precision |

Cost | Higher | Lower |

Production Speed | Slower | Faster |

Applications | High-pressure, critical strength needs | General construction, furniture, decoration |

Performance in Harsh Environments | Excellent (corrosion, wear, heat resistance) | Limited |

Wall Thickness | Suitable for thick walls | Limited to thinner walls |

Weight | Lighter for the same strength | Heavier for the same strength |

Manufacturing Process of Steel Square Tubes

The process of manufacturing steel square tubes is a complex, high-tech affair, involving a series of precise steps that produce the final product to the desired industrial standards and quality. Steel square tubes can be made by either the seamless or the welded method, each with its own set of advantages.

Raw Material Preparation

At the beginning, the process selects the highest-quality steel, which is typically in sheet metal or billet form. The selection of raw materials is based on their chemical composition and mechanical properties, indicating that they can withstand and be used for various applications.

Forming

For the welded square tubes, the steel sheet is processed by roll forming. The sheet is progressively formed into a circular shape using rollers, which provide uniform thickness and precision. The seamless tube's production involves the heating of the billet and piercing through it to obtain a hollow cylindrical form thus eliminating welding.

Welding (For Welded Tubes)

The edges of the circular steel sheet are joined using high-frequency electric resistance welding (HFERW). The welded joint undergoes testing to verify compliance with the set quality standards. Subsequently, the circular tube is transformed into a square or rectangular tube using specialized roll-forming machinery.

Sizing and Shaping

Once the square shape is achieved, the tube passes through a series of sizing rollers that adjust parameters such as wall thickness and external width to meet specific requirements. State-of-the-art equipment guarantees high-precision tolerance control to within ±0.1mm, which is usually the case.

Heat Treatment

The structural characteristics of the tube may be improved through heat treatment processes such as annealing or normalizing. This step warrants that the final product be of maximum strength, flexibility, and fatigue resistance.

Surface Finishing

Steel square tubes are cleaned, followed by pickling, polishing, or coating to protect the surface from rust. Depending on the application needs, some manufacturers use galvanizing or powder coating in addition to standard practices.

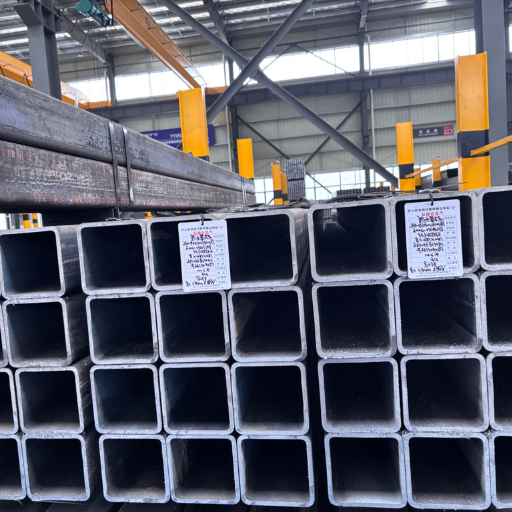

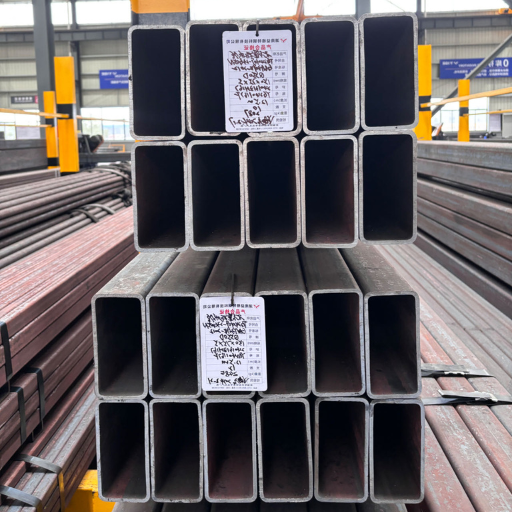

Quality Inspection

Every single steel square tube undergoes a stringent series of quality checks, including ultrasonic testing for internal defects, dimensional accuracy testing, and tensile and hardness testing. These inspections ensure that the tubes comply with internationally recognized standards, such as ASTM A500 or EN 10210.

Recent Trends and Data

Manufacturing processes have been automated, leading to streamlined operations, time savings, and cost reductions. Industry data show that manufacturing efficiency has increased by 20-30% due to the use of automated machines. Moreover, the adoption of sustainability practices, such as recycled steel use and energy-saving techniques, has become common in the industry. MarketsandMarkets has estimated global revenue from sales of square steel tubes at $50 billion in 2022, and the trend is continuing to rise due to growth in construction and renewable energy.

The manufacture of steel square tube is an ongoing process that transforms the product into an ultimate high-strength, versatile, and eco-friendly application; besides, it is still, in most cases, aligned with the demands of global industries.

Traditional Techniques vs. Modern Advancements

The production process has been constantly changing over the years, from ancient techniques to modern, still sustainable practices, and finally to very advanced modern techniques. The following are the five primary techniques that were compared to each other, and the differences between the old methods and the new ones were pointed out:

Hot-rolling vs. Cold-rolling

Traditional: Hot-rolling was the go-to method for making square steel tubes back then; the process involved heating the metal to make it easier to work. Although it was an effective method, hot-rolling was criticized for poor dimensional control and rough surface quality.

Modern: Cold-rolling technology offers up to ten times better dimensional accuracy and 1,000 times smoother surface finish, making it well-suited for applications that require high precision.

Welding Methods

Traditional: Good old manual welding rods (SMAW) were among the widespread ways of joining, but they were labor-intensive and inconsistent.

Modern: Lasers and robots have taken over and transformed the welding game, ensuring precise, uniform, and fast production.

Material Refinement

Traditional: The impurities were often the result of the refinement with limited techniques applied to crude metal and they were negatively affecting the lifespan of the product.

Modern: Advanced metallurgy uses desulfurization and vacuum degassing to produce parts that are not only cleaner but also very strong and have good performance attributes.

Surface Treatment

Traditional: Manual sandblasting or basic galvanization were, at the time, the most widely used techniques of surface protection; however, they had minimal corrosion resistance.

Modern: Sophisticated surface treatments such as powder coating, epoxy-based treatments, and advanced galvanization are currently used to provide the product with longer-lasting protection and greater eco-friendliness.

Energy Efficiency

Traditional: The production processes were highly energy-intensive, leading directly to increased carbon emissions and waste.

Modern: The adoption of energy-efficient methods, along with induction heating, has significantly reduced the production line's environmental impact by integrating renewable energy sources.

The advancements, as mentioned earlier, have, in addition to improving the quality and performance of steel square tubes, also made them compliant with sustainability and efficiency trends that are increasingly becoming global priorities.

Overview of Cold-Drawn Seamless Methods

Cold-drawn seamless methods are high-tech manufacturing processes that not only improve accuracy but also enhance the quality of steel tubes. The production technique commonly referred to as “cold drawn” involves using a die at room temperature, in which a metal tube is pulled through it without heating the tube. The cold-working process delivers wins over hot working, commonly referred to as “cold drawn,” which involves using a die at room temperature and affects surface finish, dimensional tolerances, and mechanical properties.

Steps of Cold Drawing Process:

Piercing and Tube Preparation

The first step of the procedure is piercing, and hot piercing is the most common method for forming a hollow cylindrical billet into the desired form. Every time the hollow rod is finished, it undergoes cleaning to remove scale and impurities, ensuring it is at its best for the upcoming drawing operation.

Drawing Through a Die

The cleaned tube is drawn through a die, with its diameter reduced on one side and stretched at the other. Here, utmost care is needed to get the right size and physicochemical properties.

Intermediate Annealing

To restore softness and remove hardening from successive drawing, the process usually involves heating tubes to a specific temperature and then cooling them between passes that consist of multiple drawings.

Final Sizing and Finishing

The tube undergoes final sizing and finishing operations to comply with application requirements. This operation includes the precise stapling, improvement of surface quality, and consistency in mechanical properties.

Modern Practice Efficiency and Sustainability

The latest cold-drawn seamless methods incorporate energy-saving technologies and eco-friendly practices. For instance:

The use of energy-efficient machines during the drawing operation results in a significant reduction in energy consumption.

The implementation of waste recycling systems during the manufacturing process ensures there is no loss of raw materials.

Certification with the ISO 14001 environmental standard is a clear sign of a company's commitment to sustainability.

Applications and Data Insights

Cold-drawn seamless pipes are used in a wide range of industries, including automotive, aerospace, construction, and energy. Industry analysts estimate that the global cold-drawn seamless pipe market was worth $11.9 billion in 2022 and will increase by 5.5% annually (CAGR) during the years 2023-2030. The emerging demand stems from the growing need for high-performance materials across critical industries. Tubes with key properties, such as corrosion resistance, tensile strength, and consistent dimensional accuracy, are essential in demanding applications.

The use of these advanced methods demonstrates both the technological precision and sustainabilit,y which coincide with the growing worldwide demand for high-quality and eco-friendly steel products.

Applications and Benefits of Square Steel Tubing

Square steel tubing is a versatile material that finds its way into various sectors owing to its structural integrity, durability, and adaptability. Here are five main uses of square steel tubing, along with their respective advantages:

Construction and Infrastructure

Square steel tubing has been newly adopted for a long time in the construction of buildings, bridges, and support structures. Its high strength-to-weight ratio and push load resistance mean it can take quite a lot of weight. The uniform shape provides stability during construction and facilitates easier assembly.

Automotive Sector

This material is used in the manufacture of car frames, roll cages, and body parts. The combination of its lightweight, durable nature is a blessing for vehicles, as it not only increases their performance but also reduces their fuel consumption.

Manufacturing and Industrial Material

Square steel tubing has become a necessary raw material for the eventual making of industrial machines, e.g., conveyor systems or machine frames. The two properties of corrosion resistance and dimensional accuracy ensure the equipment has a long, reliable life, even in the harshest environments.

Furniture and Interior Design

The modern, sleek look of square steel tubing makes it one of the most sought-after materials for furniture such as tables, chairs, and shelving. It can hold more weight than usual, allowing designers to create stronger, more beautiful designs that serve both entertainment and functionality.

Agriculture and Fencing

Farmers and ranchers consider square steel tubing among the most desirable materials for agricultural machines, greenhouses, and enclosures. Its toughness, along with its ability to withstand environmental conditions, makes it an ideal candidate for outdoor or rough-terrain applications.

These application examples highlight the outstanding characteristics and benefits of square steel tubing, making it indisputably the leading choice for both industrial and everyday use.

Use in Construction and Structural Applications

Square steel tubing is a construction material that is highly important in the industry for its durability, strength, and versatility. Below are five main areas where square steel tubing proves to be the best:

Building Frames

Square steel tubing is widely used in the construction of building frames. It provides structural strength and can withstand heavy loads; hence, it is a must for the construction of residential and commercial buildings.

Bridges and Overpasses

Square steel tubing is a material that is always used in the construction of bridges and overpasses by engineers. The combination of strong and corrosion-resistant traits gives the structures durability and safety during their lifespan.

Architectural Designs

Modern structures like skyscrapers and large art installations are among the designs that architects and painters use square steel tubing for, because it is so versatile and can create any style, from bold to minimal to even innovative.

Scaffolding Systems

The thick-walled square steel tubing is durable and supportive for workers, streamlining their movements during construction and repair by providing a safe, reliable platform.

Industrial Support Structures

The steel tube is square and is used in building support structures, such as platforms, stairways, and walkways, in manufacturing plants. Its resistance to bending under load and stability make it a trusted option.

These are just a few of the many applications that demonstrate the importance of square steel tubing in stabilizing and making projects involving construction or structural work functional.

Role in Automotive and Machinery Industries

The square steel tube is a key material in the automotive and machinery industries, to some extent, due to its properties such as durability, strength, and versatility. There are five main applications below:

Vehicle Frames and Chassis

Square steel tubing is the primary material used in vehicle frame and chassis construction. Its robust design enables it to carry heavy loads, thereby ensuring the vehicle's structural integrity and passenger safety.

Exhaust Systems

Due to its excellent heat and corrosion resistance, it is often used in the manufacture of car exhaust systems, which extends their lifespan.

Machinery Components

Square steel tubing is used in various heavy-duty industrial machines as parts, such as supports, braces, and housing frames, where strength is a must for heavy-duty operations.

Agricultural Equipment

Square steel tubing is used in equipment such as tractors, plows, and harvesters. Its resilience contributes to smoother operation under variable stress in agricultural environments.

Manufacturing Equipment Frames

Apart from this, the tubing is also used in the frames of various manufacturing and assembly equipment, which keeps the equipment stable and accurate during the production process.

A combination of adaptability and reliability makes square steel tubing an invaluable material for the development of automotive technologies and the improvement of engineering practices for machinery.

Market Trends and Innovations in Seamless Steel Tubes

The seamless steel tube sector is gradually and smoothly adapting to technological innovations in manufacturing and demand from different industries. The analysts have released a report stating that the global seamless steel tube market will reach $102.3 billion by 2030, and from 2023 to 2030, it will grow at a Compound Annual Growth Rate (CAGR) of 5.7%. The growth is mainly driven by the energy, automotive, and construction industries, which are expanding, and seamless steel tubes play a critical role in these sectors owing to their longevity, strength, and ability to withstand high pressure.

One trend in the market is manufacturers investing more time and money in developing eco-friendly processes. The introduction of new technologies and cleaner production of steel tubes helps control and, ultimately, reduce carbon emissions, thereby improving the steel production process and ensuring smoother flows. The use of innovative technologies, such as AI, in combination with high-tech inspection systems has helped ensure there is no poor quality, leading to fewer product rejections and, consequently, less material waste.

There has been a significant difference in demand across regions. The Asia-Pacific region continues to be the most critical market for seamless steel tube,s which is mainly due to the active industrial and infrastructure development in China. On the other hand, the North American market, which is primarily supported by the energy sector through oil and gas exploration, is gradually switching to seamless tubes for such operations.

Specialty products, such as seamless pipes that resist corrosion and are specifically designed for the chemical and petrochemical industries, are becoming increasingly popular. The production of new materials, such as stainless and duplex steels, capable of operating under extreme environmental conditions, is also underway.

To sum up, constant investments in R&D, along with changing customer preferences, are driving a vibrant, flexible future for the steel pipe industry. The industry’s technological development, market growth, and environmental programs coalesce to present both opportunities and challenges in the future.

Current Trends in the Square Steel Tube Market

Increasing Demand in the Construction Industry

Square steel tubes are gaining increasing popularity in the construction industry because of their ability to withstand heavy loads, making them ideal for building frameworks, bridges, and industrial infrastructure. The latest market research indicates that the building industry accounts for nearly 40% of global consumption of square steel tubes.

Growing Preference for Lightweight Materials

Producers are working to make square steel tubes lighter to meet demand for improved efficiency and cost reduction across several applications. These breakthroughs not only reduce the cost of the material but also help make transportation more energy efficient.

Adoption of Advanced Manufacturing Techniques

The use of advanced technologies, like laser welding and robotic fabrication, not only enables the production of square steel tubes with improved precision, durability, and production rates but also progressively accelerates market availability of high-quality products.

Expansion in Renewable Energy Projects

The use of square steel tubes in solar panel frames and wind turbine structures has been gaining widespread support amid the global shift to renewable energy. This movement is not going to stop, as renewable energy investments are expected to rise by 15% a year over the next ten years.

Focus on Sustainability and Recycling

Environmental issues are driving the adoption of pent-up production and the recycling of square steel tubes. A large number of manufacturers are making announcements regarding their initiatives to use green materials, reduce carbon footprints, etc., as part of the global sustainability push. This has contributed to an over-the-top rise in recycled steel use, which now accounts for around 30% of the total materials used by the leading players in the industry.

Emerging Applications and Specialty Tubing

The future development of the industry is being shaped by the five major upcoming applications and specialty tubing types mentioned above. Square steel tubes are gaining new and creative uses across various sectors due to their excellent properties, the availability of diverse technologies, and the strong demand for flexible, multi-functional structural solutions.

Automotive Lightweight Frameworks

The auto-makers of the modern world prefer square steel tubes for the fabrication of lightweight yet robust automobile frameworks. The car's weight is reduced by up to 25%, making it more fuel-efficient and emitting less CO2.

Green Building Infrastructure

Square steel tubing is making a significant contribution to advanced green building construction. It is one of the materials used to build energy-efficient structures, such as solar panel mounting systems, due to its long lifespan and recyclability.

Precision Medical Equipment

Medical devices such as surgical instruments and hospital beds use specialty tubing made of high-grade steel. Its resistance to corrosion and precision dimensions are significant factors in the healthcare industry.

Robotics and Automation

High-precision square steel tubes are now the backbone of the robotics sector, where lightweight design and structural integrity are the two most essential factors in the manufacture of robotic arms and automated equipment.

Aerospace Components

Specialized square steel tubing is now an essential aspect of the aerospace industry, as it provides aircraft parts with high tensile strength, temperature resistance, and compatibility with advanced alloys.

The applications mentioned above speak volumes about the advantages specialty tubing can offer in solving contemporary engineering problems. Plus, sustainability and efficiency are still considered.

Tags: seamless square steel pipe