-

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

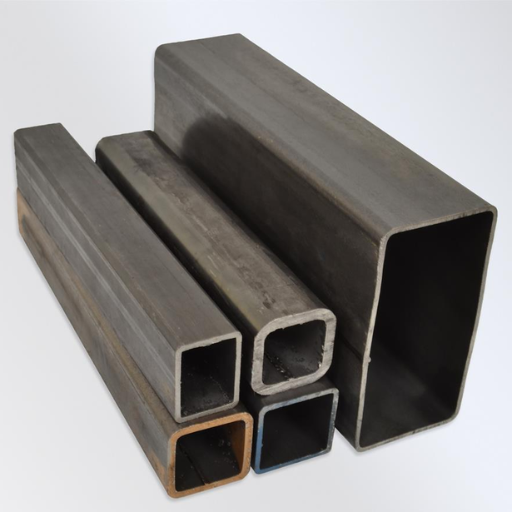

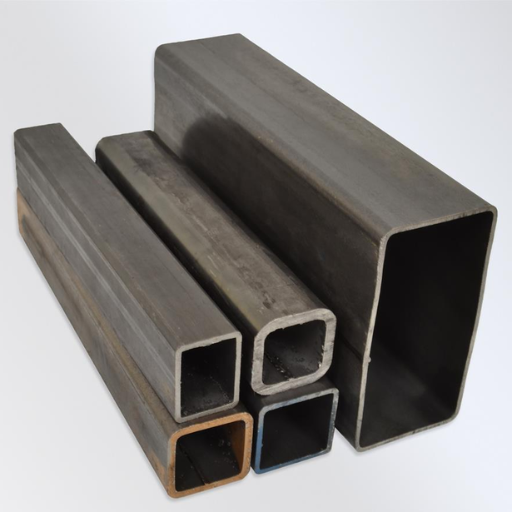

Carbon Steel Tubing: Understanding Steel and Its Applications

2025-10-23 15:14:12

Steel is significant because it supports a wide variety of industries and is therefore heavily used in various applications. One such application we know is making various structures using carbon steel tubes. It has significant advantages and is widely used for multiple purposes, including building and manufacturing. To explain this, it is better to examine where and how carbon steel tubes are helpful, what their specific features are, and why the majority of Engineering and Design experts seem to choose them. Thus, let’s look at what carbon steel tubes are, how they’re used, and what advantages they bring so that you will have all the information available to you. This advocacy, intended for those who work in this field and those interested in the seemingly complex contraption, is equally valid. It is a collection of the most essential information that you need to make that decision.

Introduction to Carbon Steel Tubing

Carbon Steel Tubing is a durable material that is commonly used in many industries because of its strength, cost, and versatility. Carbon steel contains iron and carbon as constituent elements, which ensures strong mechanical properties that can be altered depending on the application. The engineering, automotive, and building industries prefer this because of its high wear and pressure tolerance. Carbon steel tubing, however, can be recycled, which is an environmentally conscious approach in today’s societies.

What is Carbon Steel Tubing?

The material is hard and untoward, the material being made of iron and carbon, carbon steel tubing is used in construction, manufacturing and transport industries because it’s tensile strength is high, the material is pliable and the cost is low.

Key Properties of Carbon Steel

Enhances Resistance to Heavy Load

Given its considerably high tensile strength and the impact it can withstand, the material is very effective for designing complex and demanding construction and manufacturing structural requirements.

Affordability

The low prices of carbon steel, compared to other metals enhanced with alloying, make it a very desirable option for its properties, particularly mechanical efficiency.

High Conductivity

Aluminium has relatively good electrical and thermal conductivity. Accordingly, this material can be used in a wide array of thermally conductive components.

Functionality

Based on the amount of carbon contained, carbon steel can be treated to achieve various properties from softness to toughness for any structural or non-structural requirements.

Protection against Corrosion (Additional measures)

If left uncoated, carbon steel may be more prone to rust, notwithstanding any corrosion preventive coatings or treatment applied. This prolonged use of noticement parts occurs while avoiding any spare part support for an extended period.

Benefits of Carbon Steel Tubing

Resilience

More commonly, one can use Carbon Steel Tubing for piping systems subjected to high pressures and elevated temperatures. This is due to the remarkable strength and durability of the carbon steel, which allows it to withstand mechanical processes or wear and tear over time, thereby increasing its effectiveness in a tough circuit.

Frugal

Carbon steel, unlike stainless steel and other metals, is cheaper but provides equally great results. Its affordability is a reason why most industries tend to choose such options without compromising the quality provided.

Potential for Use

Carbon Steel Tubing can be used in various applications and industries, such as construction, automotive, and other energy sectors. Examples of these uses include construction, where the tubes provide structural integrity, the transportation of fluids, and components within machinery.

Simple Manufacturing

Carbon steel is advantageous to work with as it can be easily cut, bent, or formed into the required shapes. Using this feature, Manufacturers design different kinds of customized tubes to meet various industrial or commercial specifications.

High Tensile Ability

Due to the high tensile strength of carbon steel tubing, it can hold heavy loads without distorting. Therefore, heavy structures, including bridges and pipelines, are more suitable for the material as it does not easily give way under applied forces.

Durability and Strength

Carbon Steel Tubing, famous for its superb wear resistance and toughness, is the best choice for many sectors of the economy. It can easily tolerate different pressures, temperatures, and adverse conditions. The same applies to research on carbon steel, which shows that the metal can operate between -29°C (-20°F) and over +500°C (+932°F). This temperature range varies across different grades of steel, enabling high performance in several applications.

Recent statistics state that the tensile strength of carbon steel ranges from about 400 to 550 MPa, which is a lower grade, while the larger grades developed for even the taming of the most robust projects exceed 1000 MPa. Such endurance allows it to be used optimally even under heavy loads and forces, for instance, inside the tanks of factories and other forms of construction, among others.

Moreover, the structural strength of carbon steel is equally essential. According to Stoney, the factor is apparent when carbon steel tubing is used for refrigerated locomotives and road transport: “It is possible to fill the tubes with hot water and not worry about the level of impurity affected on the tubes by contact with the water” (Stoney, 1985, 203). The modern manufacture of carbon steel includes heat treatment, coating methods, and galvanizing processes, among others, to extend the service life of such items and metals. Such items and metals hence find use in the harshest conditions possible.

Cost-Effectiveness of Carbon Steel

Carbon steel is regarded as a sustainable and economic material in most industries. Its production systems are relatively cost-efficient because the materials and processes involved are readily standardized. The following five aspects make carbon steel a cheap option:

Affordable Material Prices: The cost of production of carbon steel is relatively low, given the cheapness of the key constituents that make carbon steel, that is, iron and carbon, as opposed to other metals such as aluminum and stainless steel.

Minimal Service Expenses: This is because, given the strength and stability of carbon steel structures, maintenance expenses for carbon steel systems are usually lower than those of other materials.

Producing Costs Restraint: Modern production technologies, such as electric or arc furnaces (EAF), do not consume a lot of energy, hence significantly reducing the manufacturing costs of CARBON STEEL TUBING.

Multipurpose Use: The use of carbon steel in constructions, transport means, and buildings encourages the reduction of various classes of materials and thus provides significant cost benefits.

Recyclability: As carbon steel is greatly recyclable, it facilitates industries to reduce the co

These factors collectively add to the economic benefits associated with employing carbon steel where strength, comfort and cost matter at the same time.

Comparison with Other Materials

Parameter | Carbon Steel Tubing | Stainless Steel Tubing | Copper Tubing | Aluminum Tubing |

|---|---|---|---|---|

Strength | High tensile strength | Moderate strength | Moderate strength | Lightweight, moderate strength |

Corrosion Resistance | Low, needs coatings | High, resists rust | High, resists corrosion | High, resists corrosion |

Cost | Affordable | Expensive | Expensive | Moderate |

Weight | Heavy | Moderate | Heavy | Lightweight |

Ductility | Low, brittle | High, ductile | High, ductile | High, ductile |

Applications | High-pressure, industrial use | Hygienic, marine, decorative | Plumbing, refrigeration | Aerospace, automotive, heat transfer |

Maintenance | Requires regular coatings | Low maintenance | Low maintenance | Low maintenance |

Aesthetic Appeal | Low, rough finish | High, shiny finish | Moderate, polished | High, polished |

Recyclability | Highly recyclable | Highly recyclable | Highly recyclable | Highly recyclable |

Temperature Resistance | Moderate, brittle in cold | High, withstands extremes | Moderate | High, good thermal conductivity |

Carbon Steel vs. Stainless Steel Tubing

Parameter | Carbon Steel Tubing | Stainless Steel Tubing |

|---|---|---|

Strength | High tensile strength | Moderate strength |

Corrosion Resistance | Low, needs coatings | High, resists rust |

Cost | Affordable | Expensive |

Weight | Heavy | Moderate |

Ductility | Low, brittle | High, ductile |

Maintenance | Requires regular coatings | Low maintenance |

Aesthetic Appeal | Low, rough finish | High, shiny finish |

Temperature Resistance | Moderate, brittle in cold | High, withstands extremes |

Applications | Industrial, high-pressure systems | Hygienic, marine, decorative |

Recyclability | Highly recyclable | Highly recyclable |

Carbon Steel vs. Aluminum Tubing

Parameter | Carbon Steel Tubing | Aluminum Tubing |

|---|---|---|

Strength | High tensile strength | Moderate strength |

Weight | Heavy | Lightweight |

Corrosion Resistance | Low, needs coatings | High, natural oxide layer |

Cost | Affordable | Higher than carbon steel |

Ductility | Low, brittle | High, malleable |

Thermal Conductivity | Moderate | High |

Applications | Industrial, high-pressure systems | Aerospace, automotive, lightweight needs |

Maintenance | Requires regular coatings | Low maintenance |

Recyclability | Highly recyclable | Highly recyclable |

Temperature Resistance | Moderate, weak at high temperatures | Moderate, weak under high loads |

Industry Applications of Carbon Steel Tubing

In various fields and spheres of human endeavor, there is a high demand for carbon steel, which is strong, durable, and cost-efficient. Carbon steel tubing assumed great importance in the following five industry applications:

Automotive Sector

A significant amount of carbon steel tubing is used for various applications in the automotive industry, including the manufacture of chassis, exhausts, and components responsible for structural performance. The material is known for its high strength-to-weight ratio, ensuring high safety and durability in all circumstances.

Building Construction and Infrastructure

It is highly used in sophisticated construction programs as a framework or a scaffold and also in piping and duct systems. The ability of carbon steel tubing to withstand very high stress without deforming is an advantage for structures like buildings, bridges, and tunnels.

Utilization in Oil and Gas Sector

The oil and gas industry is very dependent on tubing for the movement of raw petroleum, gas or other commodities. The high tensile and high-pressure strengths of these materials make them invaluable in applications involving pipelines, drill rigs, and refining equipment.

Mechanical/Industrial Equipment

Carbon steel tubing is a common feature of many industrial manufacturing equipment, such as conveyor belts, hydraulic systems, and framework structures. This aspect increases the effectiveness of the equipment as well as its life span.

Power Generation Industry

Carbon Steel Tubing finds an extensive number of applications in power plants and renewable energy systems. Due to its high temperature and pressure resistance, it is essential in the manufacture of different components such as boiler tubes, turbines, and other power-generating equipment.

It can be seen from every case that carbon steel tubing is a versatile and dependable component for heavy industries.

Construction and Structural Applications

Carbon Steel Tubing is an essential component used in building and construction because of its strength, sturdiness and adaptability to different applications. Below are five major areas where Carbon Steel Tubing is often applied.

Frames for Buildings

Carbon steel tubing is applied in the construction of building frames so as to provide some firmness and help avoid any pressure to the ceilings. This is owing to its tensile strength, which enables it to carry heavy weights without yielding over time.

Bridge building

One of the characteristic features of carbon steel tubing is its long-lasting nature, which is why it is actively used in bridge construction. Its endurance to the elements and heavy stress is the reason it performs excellently for prolonged periods.

Construction of Scaffolding

Owing to its capability to build a solid base from which construction workers and materials are evolved, scaffolding frameworks mainly consist of carbon steel tubing.

Massive Storage Spaces

The use of carbon steel tubing is common in the construction of industrial warehouses. It offers a firm framework needed for setting up large I-load carrying storage facilities and optimizes the use of available storage space.

Transportation Infrastructure

Railway stations, airport terminals, bridges, and tunnels for highway or rail transport are examples of carbon steel tubing projects that require calculated strength and creativity in structural designs to fulfill their intended purposes.

The application in each of these designs is so crucial that carbon steel tubing is used in constructions focusing on both durability and performance.

Automotive and Transportation Industries

Carbon Steel Tubing is one of the most widely used materials in the transport industry and automotive manufacturing. They frame various components around the cab, offering all-weather protection from the elements with minimal weight and cost. Some of these components include:

Body Frames and Chassis

Numerous manufacturers use carbon copper tubing for building vehicle structural elements such as body frames and car chassis.

Exhaust Components

This mileage feature extends the economic life of vehicles significantly, as carbon steel is corrosion-resistant and durable enough to be used in exhaust platforms or pipes.

Braking and Lifting

Strong carbon steel tubing is used in hydraulic systems inside vehicles. This has been made possible because of its capacity to resist extreme pressure, especially in the braking and lifting of a vehicle.

Fuel Pipe Systems

Strong and durable carbon steel tubing is used for fuel lines because it does not leak fuel and efficiently withstands most types of fuels under different pressures.

Railway and Shipping Parts and Components

It is present in everything from train carriages to ships - carbon steel tubing is an essential component in transportation because it supports heavy loads and is highly resistant to extreme pressures.

Carbon steel tubing has established itself as a fixture in the automotive industry thanks to its strong features and easy-to-use nature.

Tags: Carbon Steel Tubing