-

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Melody

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Seamless Rectangular Steel Pipe: Understanding Its Importance and Applications

2025-10-27 16:21:27

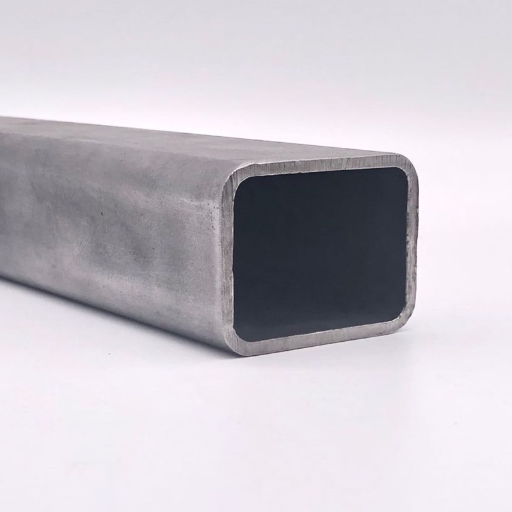

Steel pipes are essential across a wide range of industries, as they are a key component of infrastructure, transportation, and construction. Of all the different kinds of pipes, seamless rectangular steel pipes are the ones most often discussed because of their unique combination of strength, durability, and versatility. The process of making these pipes without welded seams gives them better ability to take loads, hence they are the first choice for stressful applications. But what really are the factors that make seamless rectangular steel pipes so important, and in what way do they contribute to the success of projects in different fields? This blog will answer these questions by taking an in-depth look at the pipes' key attributes, their practical applications, and the reasons they have earned the title of the most essential materials in current engineering and fabrication. Regardless of whether you belong to the field or are just interested in industrial breakthroughs, this article will be packed with enough information to help you understand the significance and usefulness of this incredible product.

History of Seamless Rectangular Steel Pipes

Seamless rectangular steel pipes were developed through advances in steel manufacturing and the Industrial Revolution. Improved steelmaking techniques and the invention of methods, such as the Bessemer process, enabled the production of large quantities of high-quality steel. Dependability on a broader range of durable, easy-to-work-with materials led to the development of seamless pipes, the first of which were produced in the late 19th century. The new pipes were stronger and less prone to defects than their welded counterparts, making them suitable for industrial and construction applications. The need for a rectangular cross-section stemmed from construction and engineering requirements, where exact dimensions and high loading capacity were essential. Seamless rectangular steel pipes have thus become indispensable elements of modern-day infrastructure and manufacturing.

Early Developments in Steel Tubing

Steel tubing originated in the earliest materials and industrialization techniques. The early 1800s saw the birth of the pipe system that would eventually support the water and steam engine industries, among others. But to come to the level of steel production where high-quality and large amounts of the material could be passed around, the Bessemer process had to come in the 1850s. This was when steel tube production became seamless, and the new century enabled the implementation of technologies for roller placement and mandrel design. The Mannesmann brothers were the ones who really changed the game for the industry with their method of making seamless tubing, thereby eliminating the need for welding and giving the pipes a significant strength boost.

Today, as per the market analysis reports, the market for seamless steel pipes is still going strong and is estimated to be around $9 billion worldwide in the year 2021 and will reach over $15 billion by 2030. The industry of oil and gas, automotive, and construction, with its toughness and precision requirements, is the main reason for such growth. Today, steel tubing is processed using the most advanced methods, including continuous casting and controlled rolling, resulting in pipes with excellent tolerances. The journey from simple systems to super-products is a reflection of steel tubing's role in economic and industrial development.

Evolution of Seamless Manufacturing Techniques

The advancement of seamless manufacturing methods has changed the game in steel tubing manufacturing, enabling greater precision, longer life, and improved product performance across various sectors. In the following paragraphs, the major five techniques that contributed to the evolution of seamless manufacture are listed:

Rotary Piercing Process

It is a process where a solid cylindrical billet is rotated and at the same time, pushed through a pair of cone-shaped rolls. Subsequently, the billet is pierced to form a hollow tube that is strong and uniform in size. This method is used extensively in industries that need tubing that can withstand high pressure and are resistant to corrosion.

Mandrel Mill Process

In this process, a mandrel is used to maintain the tube's inner dimensions as it is stretched to the correct size. Dimensional tolerances and surface finishes of the highest quality are characteristics this method provides, making it suitable for precision applications in the automotive industry, among others.

Continuous Casting and Rolling

The combination of casting and rolling leads to a considerable decrease in waste and, at the same time, improvements in the metallurgical properties. The technique involves the quick solidification of the molten steel followed by rolling it into specific shapes. Thus, the company can lower its production costs while maintaining its good reputation for quality.

Plug Mill Process

A stationary mandrel and a rotating plug are the key components of the plug mill method which refines the wall thickness of the tube. It is a very efficient method for producing thick-walled tubes with good mechanical properties.

Extrusion Process

The production of seamless tubes involves pushing a heated billet through a die to produce high-quality tubing with good strength and a uniform internal structure. The extrusion process is typical of industries where reliability is extremely important, such as aerospace and defense.

Every one of these techniques has played a part in the development of seamless manufacturing, energizing the modern industries with a spirit of innovation and flexibility.

Manufacturing Process of Seamless Rectangular Steel Pipes

The production of seamless rectangular steel pipes requires several accurate, advanced techniques to ensure high-quality output. The following gives a detailed description of the process:

Selection of Raw Material

First, the decision to use high-grade steel billets is made. Usually, these billets are made of carbon steel, alloy steel, or stainless steel, depending on the application. Besides, it is paramount to ensure the material’s purity as this will be the key to the mechanical properties’ optimum value.

Heating and Piercing

In a rotary hearth furnace, the steel is heated to 1200-1300 °C, making it very easy to work with. The next step is to pierce it with either a mandrel or a piercing mill. This process can produce a tube-shaped body while preserving the material's original strength and thickness.

Tube Rolling and Sizing

The pipe manufacturing process continues with elongation and rolling of the hollow shell through a series of rolling mills, including a plug mill or a mandrel mill. Continuous die rolling and shaping enable the rectangular cross-section to be obtained. The dimensions of the pipes are controlled with great accuracy to satisfy the requirements of standards such as ASTM A500 or EN 10219.

Heat Treatment

As a result, the seamless pipe possesses a property typically associated with heat-treatment processes such as annealing, normalizing, or quenching. This, in turn, increases its strength, durability, corrosion resistance, and toughness.

Straightening and Cutting

The pipe is straightened at the heat treatment stage using a straightening machine to eliminate any potential deformations. After that, the pipe is cut to the requested lengths, which may range from standard industry sizes to specific measurements.

Surface Treatment and Coating

The pipe surface is treated to remove dirt, rust, and scale. After that, coatings such as galvanization are applied to improve corrosion resistance and prolong the product’s life.

Quality Testing and Inspection

Steel pipes that are not made with seams and have a rectangular shape are put through a battery of tests which ensures they are in line with the industry standards. The non-destructive testing methods, such as ultrasonic testing, hydrostatic testing, and visual inspections, will be done to find defects, check dimensional accuracy, and confirm material consistency.

Data on Global Demand and Production Trends

According to the latest industry reports, the worldwide market for seamless rectangular steel pipes was valued at more than USD 22 billion in 2022 and is estimated to expand at a compound annual growth rate (CAGR) of 5.4% during the period 2023 to 2030. The main factors behind the growth are increased use in the construction, automotive, and energy sectors, especially for applications requiring high strength and reliability.

To achieve a safer, more reliable product with high worldwide demand, manufacturers are still improving the production of seamless rectangular steel pipes, using technology and strict quality standards as their main tools.

Overview of Production Techniques

The production of seamless rectangular steel pipes involves multiple modern technologies to ensure accuracy, durability, and top performance. The main step starts with the choosing of top-notch raw materials, which are generally billets or solid steel bars, plus they are heated and then pierced to form a hollow tube. Among the series of operations done are elongation, reduction, and finishing, which give the pipe its eventual rectangular shape.

Contemporary developments have introduced new methods, such as mandrel rolling and plug mill technology, to boost the productivity of seamless pipe manufacturing, among others. Mandrel rolling is beneficial for achieving uniform wall thickness throughout the pipe, while plug mill rolling is associated with the production of pipes with high-quality surfaces and dimensional precision.

Recent industry statistics indicate that producers are progressively implementing automation and AI-enabled quality control systems. These systems are wonderful in identifying tiny faults in the production line instantly and keeping compliance with the international standards, namely ASTM and EN specifications. For example, the implementation of hot extrusion and cold drawing methods has been reported to cut production time by 15-20% while raising precision by more than 30%.

Moreover, the production methods are influenced by environmental factors. EAF (Electric Arc Furnaces) are now widely used because they use recycled steel as their raw material, thereby reducing CO2 emissions by up to 35% compared to traditional blast furnaces. This kind of eco-friendly practice supports the global ambition to reduce the carbon emissions from industrial manufacturing methods.

Raw Materials and Their Importance

Raw materials form the foundation of industrial manufacturing and directly affect the quality, efficiency, and sustainability of the entire production process. The use of good-quality and suitable raw materials leads to less waste, lower costs, and better compliance with environmental standards. Below are the five significant raw materials and their importance:

Iron Ore

The most important component of steel production, and nearly all (98%) of the mined iron ore goes into steel-making.

High-grade iron ore makes the removal of impurities more effectiv,e and hence stronger and longer-lasting steel.

Coal

A significant energy source in industries and for steel making if coke is produced from it, especially during the initial stages of production.

The application of cleaner coal technologies can bring down pollution by 20-25%.

Limestone

An essential part of the process that gets rid of impurities from molten metals in steel production.

Works as a flux, reducing energy costs and ensuring the smooth running of the process.

Recycled Steel

Gradually becoming more common in steel-making, it accounts for 30-40% of raw material input in electric arc furnaces.

It reduces CO2 emissions and helps conserve the natural resources of iron ore and coal.

Nickel

It is necessary to produce stainless steel and other alloys due to their anti-corrosive properties.

The demand for nickel is growing steadily due to its use in electric vehicle batteries, thereby indirectly supporting the development of environmentally friendly technologies.

Proper management and sourcing of these raw materials will sustain and enable eco-friendly, economically feasible manufacturing practices.

Benefits of Seamless Rectangular Steel Pipes

Enhanced Strength and Durability

Seamless rectangular steel pipes are manufactured without welds or seams, providing them with exceptional structural integrity.

Their high resistance to pressure and mechanical stress allows them to be used in a heavy-duty manner across the industries.

High Corrosion Resistance

Seamless steel pipes boast excellent corrosion and rust resistance due to their sophisticated production process.

This characteristic makes them a good choice for poorly drained areas or chemical applications where moisture or chemicals are involved.

Improved Aesthetic Appeal

Seamless pipes shiny and smooth surface finish contributes to their beauty.

They are favored in construction projects that require an elegant, sophisticated look.

Versatile Application

Seamless rectangular steel pipes offer a combination of strength and flexibility, making them suitable for a variety of industries, including construction, automotive, and mechanical engineering.

Moreover, their distinctive shape enables efficient space utilization in construction.

Cost-Effectiveness Over Time

Though there is a slight increase in the initial outlay, the seamless rectangular steel pipes remain the cheaper option in the long term because they require less maintenance and repairs, and this is why they have a longer lifespan than the alternatives.

Comparative Advantages Over Welded Pipes

Key Parameter | Seamless Pipes | Welded Pipes |

|---|---|---|

Strength | Uniform, no weak weld seams | Weaker at weld seams |

Pressure Resistance | High, suitable for critical applications | Lower, limited by weld strength |

Corrosion Resistance | Superior, no weld-related vulnerabilities | Prone to corrosion at weld seams |

Durability | Excellent, withstands high stress | Moderate, welds may fail under stress |

Aesthetic Appeal | Smooth, uniform appearance | Visible weld seams |

Flow Efficiency | Minimal turbulence, smooth interior | Potential turbulence at weld seams |

Temperature Tolerance | Handles high temperatures effectively | Limited by weld material properties |

Manufacturing Precision | High, consistent dimensions | Variable, depends on weld quality |

Cost | Higher due to complex production | Lower, simpler manufacturing process |

Size Availability | Limited, smaller diameter options | Wide range, including large diameters |

Mechanical Properties of Seamless Tubing

Seamless tubing has excellent mechanical properties, making it suitable for use across various industrial sectors. The following are the five main mechanical properties of seamless tubing:

High Tensile Strength

Seamless tubing is recognized for its high tensile strength, which enables it to withstand considerable force without fracturing or deforming.

Example Value (typical for steel): 450–650 MPa (megapascal).

Superior Corrosion Resistance

The uniform structure that nature attains during its production gives it superior resistance to corrosion and chemical exposure.

Best suited for places where chemicals or moisture are present.

Excellent Thermal Stability

Seamless tubing, when subjected to high temperatures, behaves similarly to metal; thus, it is well suited for high-heat applications.

Example Operating Range (depending on material): up to 1200°F (650°C).

High Ductility

The weldless production technique allows seamless tubing to exhibit high ductility, which facilitates its manufacturing.

This quality is highly significant in operations such as bending, forming, and machining.

Impact Resistance

Seamless tubing can withstand sudden shocks or impacts; thus, it is very reliable in applications where dynamic forces are at play.

This sturdiness ensures that structural and mechanical systems are not only improved but also remain safer and more durable.

Applications of Seamless Rectangular Steel Pipes

Construction and Infrastructure

Seamless rectangular steel pipes are chosen for building frames, bridges, and other structural components primarily because of their high strength and durability. Their ability to withstand heavy loads and deformations makes them suitable for high-stress environments and for use as the main support for structures.

Automotive Industry

These pipes play a key role in the manufacturing of car parts, such as chassis and roll cages. The combination of their light weight and their superb impact resistance enhances the vehicle's performance and safety.

Oil and Gas Industry

Seamless rectangular steel pipes play a prominent role in the oil and gas sector and are primarily used to transport oil, gas, and other fluids under high pressure. The seamless construction prevents leaks, making operations more reliable and efficient.

Mechanical Engineering

These pipes are commonly used in the manufacture of industrial machines and equipment; they add strength and precision to the structure. They can be used in processes that call for very intricate bending or forming of procedures.

Renewable Energy

Wind turbine structures and solar panel mounting systems are examples of applications where seamless rectangular steel pipes have been integrated. Factors such as durability and the ability to withstand harsh environmental conditions make these materials ideal for the long-term performance of renewable energy installations.

Industry Use Cases: Construction and Beyond

Seamless rectangular steel pipes are widely recognized as the backbone of various industries due to their robustness, adaptability, and affordability. Here is a thorough investigation of the potential uses along with recent statistics:

Construction Industry

These pipes have become a necessity in contemporary construction because of their capability to bear heavy loads, such as providing support for frameworks, flooring systems, and architectural designs.

A recent report by Grand View Research (2023) forecasts that the structural steel market will grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030, reaching $151.76 billion by 2030. Rectangular steel pipes are a significant contributor to this growth, providing sustainable, lightweight solutions.

Transportation

Seamless steel pipes are not only durable, but they also encourage the use of materials in the automotive and railway industries such as chassis, safety barriers, and bridge reinforcements. To illustrate, electric vehicles rely heavily on lightweight steel components to improve efficiency.

According to a 2023 report by MarketsandMarkets, the automotive steel tubing market is anticipated to grow at a CAGR of 6% over the 2023-2028 forecast period, with rectangular pipes meeting the highest safety standards.

Renewable Energy Sector

Seamless rectangular steel pipes are basic constructive elements for the sustainable development of wind turbines, solar panel mounts, and hydroelectric structures. Their excellent corrosion resistance and ability to withstand harsh weather conditions make them the perfect choice for the renewable energy sector.

The International Renewable Energy Agency (IRENA) noted in its 2023 report that the global wind power market grew by 9% over the past year, driving higher demand for steel pipes used as structural components.

Industrial Equipment

Seamless rectangular pipes have become the standard for heavy-duty machines, agricultural tools, and industrial equipment as their robustness is considered a primary requirement. They are used in applications that require not only precision engineering but also durability.

A report published by Research and Markets in 2023 claims that worldwide investments in industrial manufacturing plants are growing at an annual rate of 4.3%, thus increasing the need for reliable structural steel materials.

Urban Infrastructure

Seamless rectangular steel pipes are also instrumental in the production of street furniture, stadiums, and transport hubs; they provide not only functionality but also modern design elements.

According to the data released by the American Institute of Steel Construction (AISC), around 2023 steel will account for more than 65% of urban infrastructure projects, indicating its significant role in making the new cities of tomorrow.

The data-backed insights unmistakably demonstrate the extensive applications of rectangular steel pipes, alongside the rising demand for seamless rectangular steel pipes across many sectors, thereby affirming their role as a decisive material in both construction and industrial development.

Typical Applications in Mechanical Tubing

Mechanical tubing products have been employed by various industries because of their strength, longevity, and flexibility. The five applications presented below, along with the respective details and data, demonstrate the significance of these applications:

Automotive Parts

Mechanical tubing is used in the automotive sector for a wide range of applications, including the production of drive shafts, suspension parts, and structural support beams. Its ability to reduce weight without compromising strength improves a vehicle's performance; however, safety remains a key concern. Steel tubing accounts for around 20% of all automotive structural components, according to industry analysis.

Building Frames

Structural steel tubing is an essential material for the framing of buildings, bridges, and other civil works. The seamless rectangular design greatly increases load-carrying capacity; studies have shown that steel tubing can save up to 15% in material costs compared to solid steel frameworks while remaining efficient.

Industrial Equipment and Machinery

Mechanical tubing is an essential material used in the construction of industrial equipment such as conveyors, hydraulic systems, and farm machinery. Its exact size and resistance to corrosion make it a material that offers high durability and reliability, even under stress.

Furniture and Fixtures

Steel tubing has become an integral part of the furniture industry for modern, durable designs for seating, tables, and bed frames. The tubing's seamless surface delivers a good-looking finish, while its strength enables creative designs. Statistics show that demand for steel-framed furniture has increased by 12% over the last five years, driven by its modern look.

Sports and Recreation Products

In addition, steel tubing is widely used in the production of recreational and sports equipment, such as bicycles, gym equipment, and children's play areas. Its combination of lightness and strength is just right for supporting dynamic movements and weight. Manufacturers of recreational equipment have achieved up to a 10% reduction in production costs by using tubular steel components.

Tags: seamless rectangular steel pipe